XIN LI

Xinli is a highly reputable supplier of high-purity abrasives, serving over 50,000 customers worldwide.

- ✅ounded year: 2003

- ✅Factory area: 200,000 square meters

- ✅Number of Workers: 1000+

- ✅Production equipment: 500 sets

- ✅Global customers: 50000+

or Call +86-15890168176

Why is our alumina so pure?

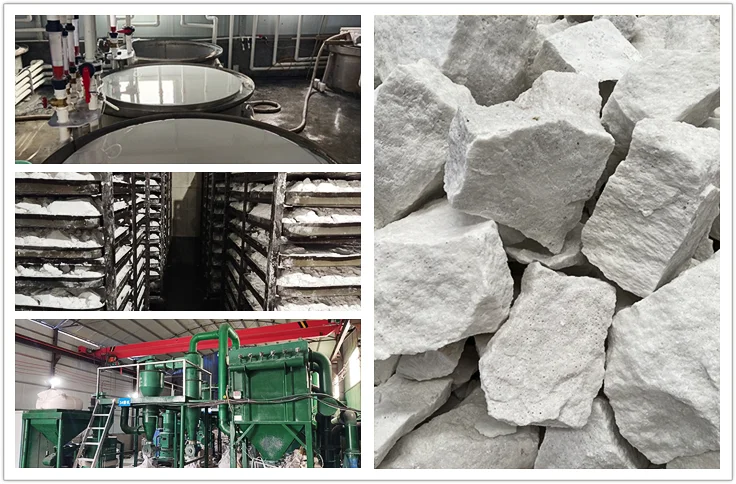

🧪1. High raw material purity

We select high-grade aluminum sources (such as high-purity aluminum hydroxide or high-purity metallic aluminum) as raw materials.

⚙️2. More Refined Production Processes

Using high-purity refining processes such as the chlorination-oxidation method, the alcoholate method, or the high-purity Bayer process, the purity of alumina can reach over 99.99%.

🧰3.Strict equipment and environmental control

The production process is conducted in a clean, inert atmosphere environment. Equipment materials utilize contamination-resistant substances such as quartz or Teflon to prevent the introduction of secondary impurities.

🔬4.Improved Inspection and Quality Control

Utilizing precision instruments such as ICP-MS and XRF for detection, we strictly control impurity levels of Na, Fe, Si, Ca, and other elements to ensure batch-to-batch consistency.

our Products

Featured Products

Application scenarios

Sandblasting & Rust Removal

White fused alumina is ideal for industrialsandblasting and rust removal. lts high hardness andsharp angular shape enable efficient cleaning ofstainless steel, aluminum, and glass surfaces without

contamination.

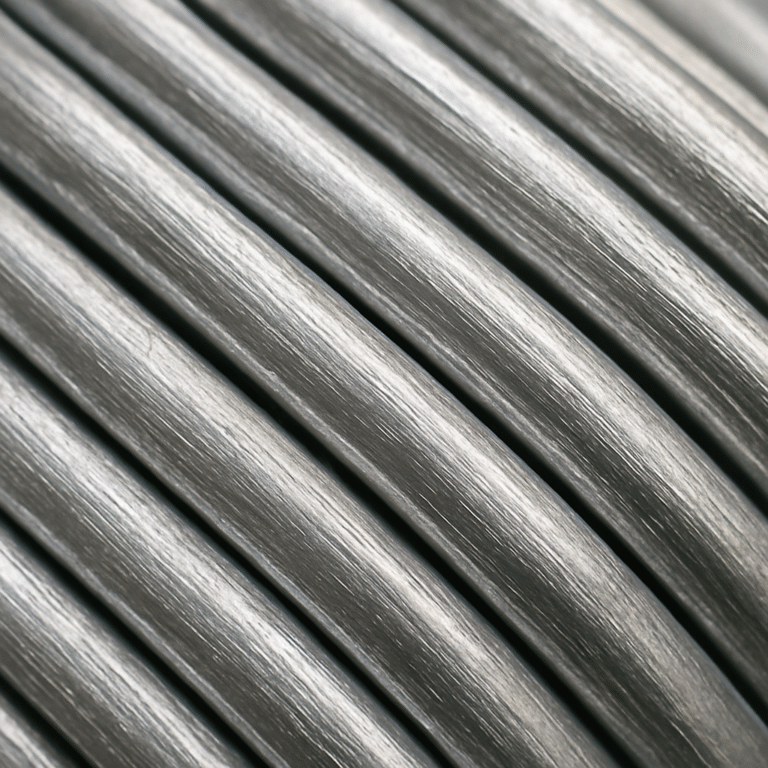

Metal & Stainless SteelPolishing

Fine-grain alumina powders are used in metal andstainless steel mirror polishing. With controlledparticle size and high purity, it produces smooth,reflective surfaces for molds, kitchenware, andprecision components.

Silicon Wafer Cutting

White fused alumina is used as an abrasive in multi-wire saws for silicon wafer slicing. lts uniform hardnessand thermal stability ensure precise, smooth cuts withminimal chipping in semiconductor and solar wafer

processing.

Optical Lens & LED Screen

Polishing

Ultra-fine alumina powders are used for highprecision polishing of lenses, LED substrates, and glasspanels. They provide excellent surface flatness andoptical clarity for display and imaging applications.

Abrasive Tools Manufacturing

White fused alumina is a primary raw material formaking sandpaper, grinding wheels, and oil stones. ltoffers strong bonding strength, sharp cutting action,and long service life in both bonded and coated

abrasives.

Advanced Ceramic &Insulation Materials

High-purity white fused alumina is used in wear-resistant and insulating ceramics. lt enhanceshardness, electrical insulation, and corrosionresistance, suitable for electronic components andstructural ceramics.

Global sales network

To date, our clients are located in many countries across Asia, Africa, North America, South America, Europe, and Oceania.

Our Product — High Purity Alumina

We specialize in manufacturing high-purity alumina, widely used in ceramics, catalyst carriers, polishing materials, and electronic components. Our alumina features excellent thermal stability, chemical inertness, and dispersion performance, making it the ideal choice for high-end industrial applications.

HSA has served over 100 global clients, providing premium alumina and technical support to help partners achieve efficient and sustainable production

- ✅ 99.99% High Purity Alumina

- ✅Customizable Particle Size (Micron/Nano)

- ✅OEM / ODM Support

- ✅Free Samples and Test Reports

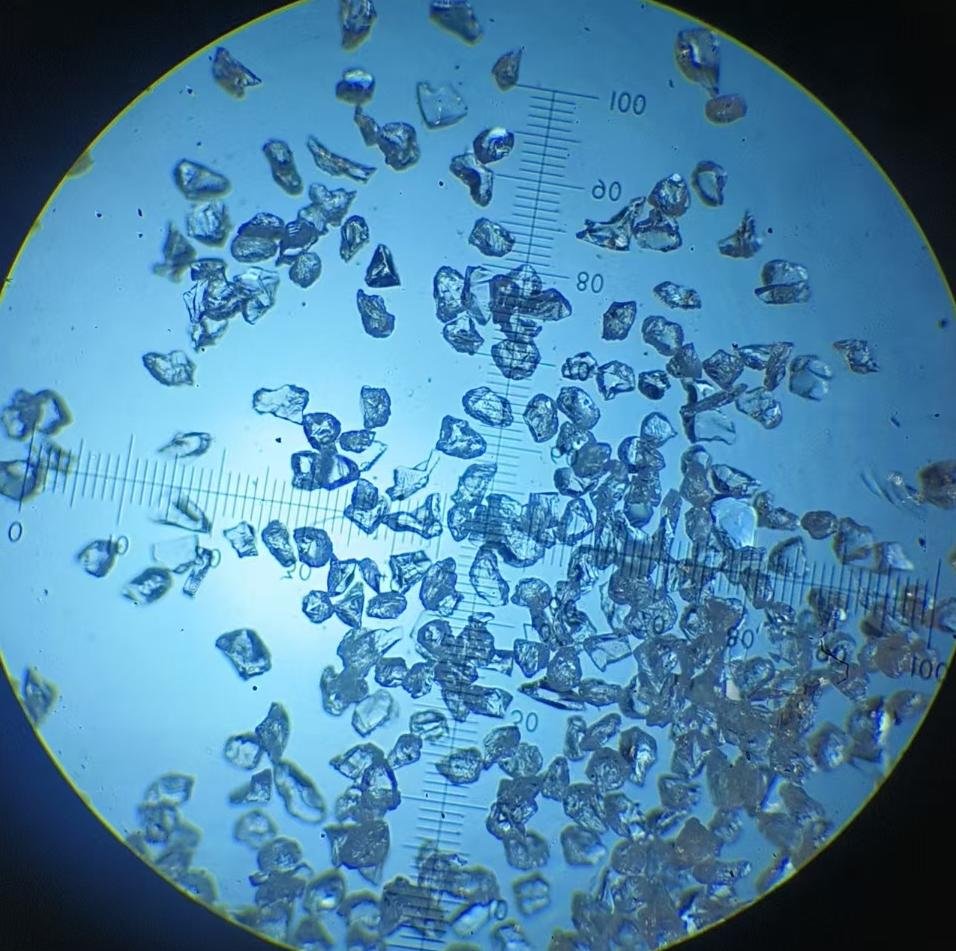

![white corundum#16[2] White fused alumina grits #16](https://wfabrasive.com/wp-content/uploads/2022/01/white-corundum162-300x300.jpg)

![white corundum#20[2] White fused alumina grits #20](https://wfabrasive.com/wp-content/uploads/2022/01/white-corundum202-300x300.jpg)

![white corundum#24[2] White fused alumina grits #24](https://wfabrasive.com/wp-content/uploads/2022/01/white-corundum242-300x300.jpg)

![white corundum#60[2] White fused alumina grits #60](https://wfabrasive.com/wp-content/uploads/2025/11/white-corundum602-300x300.jpg)