XIN LI

Xinli is a highly reputable supplier of high-purity abrasives, serving over 50,000 customers worldwide.

- ✅ounded year: 1996

- ✅Factory area: 200,000 square meters

- ✅Number of Workers: 1000+

- ✅Production equipment: 500 sets

- ✅Global customers: 50000+

or Call +86-15890168176

About XINLI Materials

High-Performance White Fused Alumina & Micron Powder Specialist Since 1996

At XINLI Materials, we have spent nearly 30 years helping global manufacturers improve their cutting, grinding, polishing, and surface-finishing performance. Founded in 1996, our company has grown into a trusted supplier of premium white fused alumina and ultra-fine micron powders for customers across Europe, America, and Asia.

Today, we operate advanced production lines with an annual micron-powder capacity of 5,000 tons, delivering consistent quality and large-volume supply for industrial users worldwide.

our Products

Featured Products

Application scenarios

Sandblasting & Rust Removal

White fused alumina is ideal for industrialsandblasting and rust removal. lts high hardness andsharp angular shape enable efficient cleaning ofstainless steel, aluminum, and glass surfaces without

contamination.

Metal & Stainless SteelPolishing

Fine-grain alumina powders are used in metal andstainless steel mirror polishing. With controlledparticle size and high purity, it produces smooth,reflective surfaces for molds, kitchenware, andprecision components.

Silicon Wafer Cutting

White fused alumina is used as an abrasive in multi-wire saws for silicon wafer slicing. lts uniform hardnessand thermal stability ensure precise, smooth cuts withminimal chipping in semiconductor and solar wafer

processing.

Optical Lens & LED Screen

Polishing

Ultra-fine alumina powders are used for highprecision polishing of lenses, LED substrates, and glasspanels. They provide excellent surface flatness andoptical clarity for display and imaging applications.

Abrasive Tools Manufacturing

White fused alumina is a primary raw material formaking sandpaper, grinding wheels, and oil stones. ltoffers strong bonding strength, sharp cutting action,and long service life in both bonded and coated

abrasives.

Advanced Ceramic &Insulation Materials

High-purity white fused alumina is used in wear-resistant and insulating ceramics. lt enhanceshardness, electrical insulation, and corrosionresistance, suitable for electronic components andstructural ceramics.

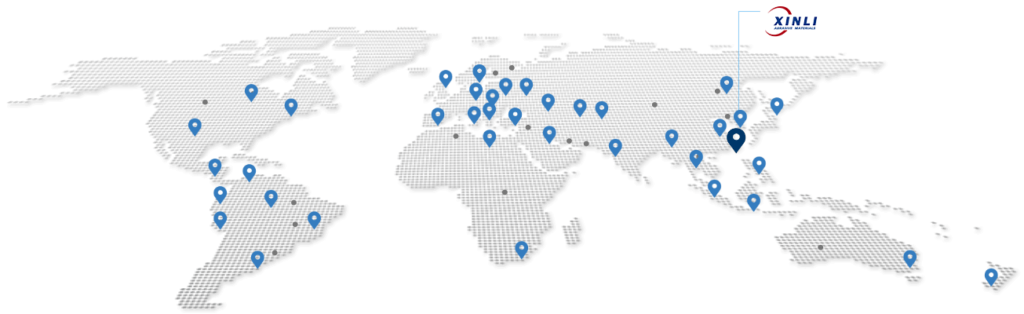

Global sales network

To date, our clients are located in many countries across Asia, Africa, North America, South America, Europe, and Oceania.

Our Product — High Purity Alumina

⭐ What Makes XINLI Different?

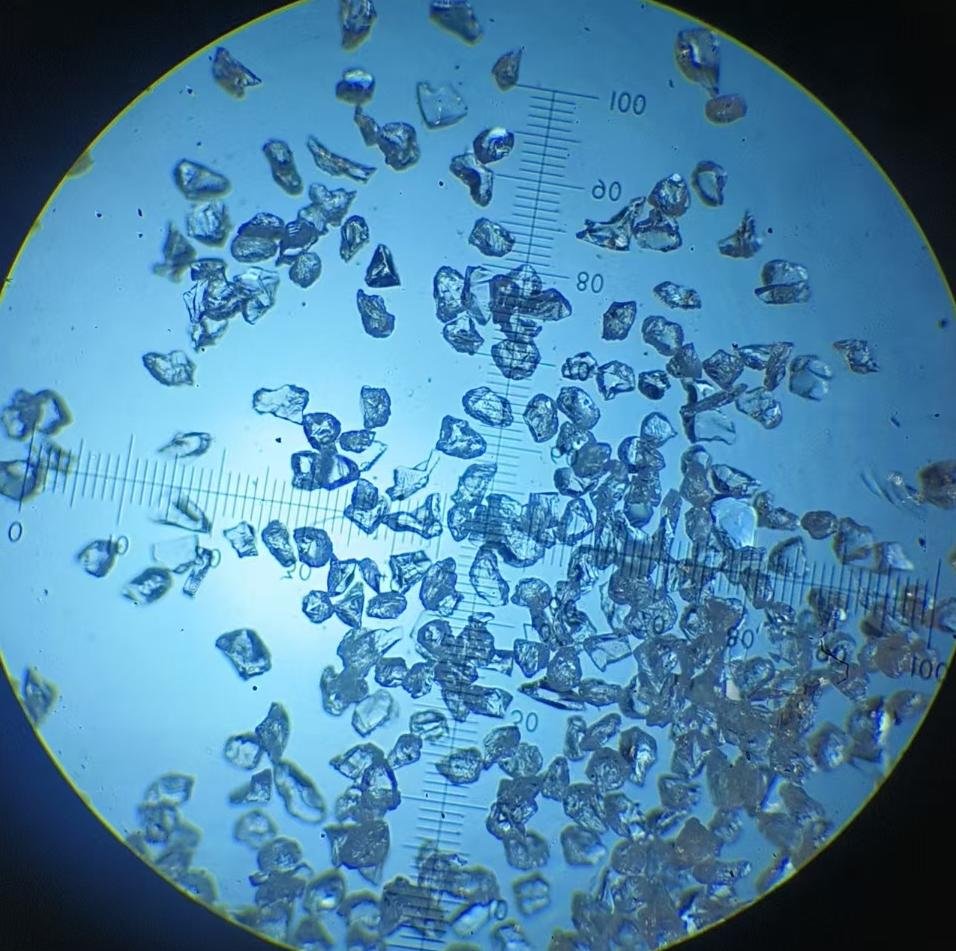

✔ Industry Leader in Ultra-Low-Sodium WFA

Our low-sodium white fused alumina (0.05 – 0.25% Na₂O) is our top-selling product, widely used in:

- Precision polishing

- Coated abrasives

- High-end grinding tools

- Ceramics & electronic components

Our Product Portfolio:

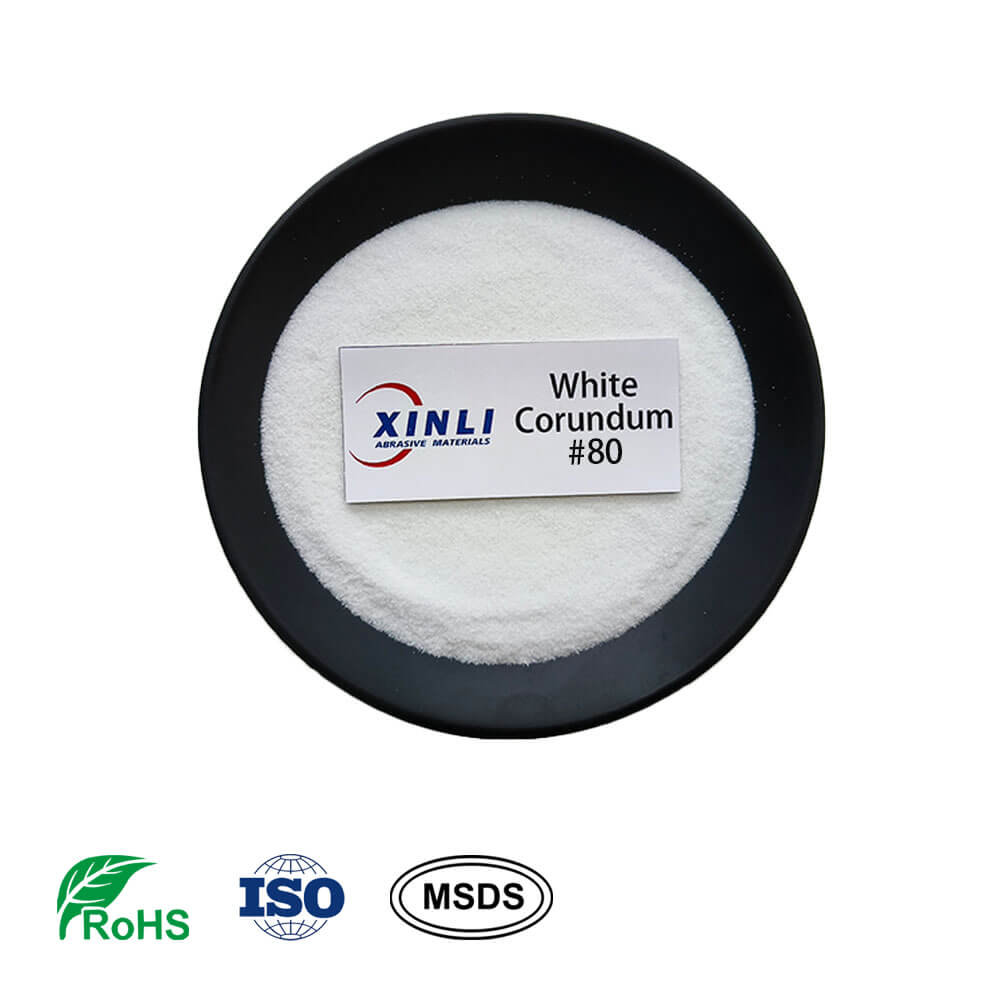

White Fused Alumina (WFA / WA)

- F Grit: F12–F220 (bonded abrasives)

- P Grit: P12–P240 (coated abrasives)

- FEPA Micron Powder: F230–F1200, 1–63 μm

- JIS Micron Powder: #240–#8000

- Ultra-Fine Powder: 0.3–1 μm (mirror polishing)

- Low-Sodium WFA (0.05-0.25% Na₂O)

- High-Purity WFA

Latest From Our Blog

Alumina Explained: Manufacturing, Properties, White Fused Alumina & Market Price

Featured Snippet Summary Alumina, also known as a…

Corundum White: Properties, Industrial Uses, and Buyer Selection Guide

What Is Corundum White? Corundum white, commonly …

Understanding the Properties of Alumina stone

Alumina stone is a fascinating material with uniq…

Understanding the Density of Alumina Materials

Alumina, also known as aluminum oxide, is a mater…