Alumina ceramics are a marvel of modern materials science. Known for their exceptional durability, they are a staple in many industries.

But what makes alumina ceramics so durable? Their unique properties set them apart from other materials.

These ceramics are not only tough but also versatile. They find applications in everything from electronics to aerospace.

Understanding the durability of alumina ceramics requires a closer look at their properties. This includes their hardness, toughness, and resistance to wear.

In this article, we will explore the factors that contribute to the durability of alumina ceramics. We’ll also examine their applications and technological advancements.

What Is Alumina Ceramic?

Alumina ceramic, also known as aluminum oxide, is a crystalline compound. It forms the basis for a wide range of ceramics. This material stands out due to its exceptional hardness and thermal stability.

The production process includes several key steps. These involve:

- High-temperature firing

- Sintering to enhance mechanical properties

- Precision shaping and polishing

Alumina ceramics can withstand harsh conditions, making them versatile. They are used in industries like aerospace and electronics. The ability to maintain their integrity at high temperatures is vital. This property ensures reliable performance in demanding applications.

Key Alumina Properties That Influence Durability

Alumina’s durability is influenced by a range of properties. Its high melting point, over 2000°C, is remarkable. This makes it suitable for high-temperature applications. These conditions are common in industries like metallurgy and electronics.

Chemical resistance is another critical factor. Alumina ceramics resist corrosion from acids and bases. This property increases their lifespan even in harsh environments. Many industries benefit from this chemical resilience.

Mechanical strength is another significant contributor. Alumina has high compressive strength, maintaining structure under pressure. This quality is essential for structural applications. It allows the ceramic to withstand heavy loads.

Electrically, alumina shines as an insulator. Its dielectric strength is high, making it invaluable in electrical applications. This insulation property reduces the risk of electrical failures. Key properties of alumina include:

- High thermal stability

- Exceptional chemical resistance

- Excellent mechanical strength

- Superior electrical insulation

These properties work together to enhance alumina’s durability. They ensure that the material can endure severe conditions, maintaining performance over time.

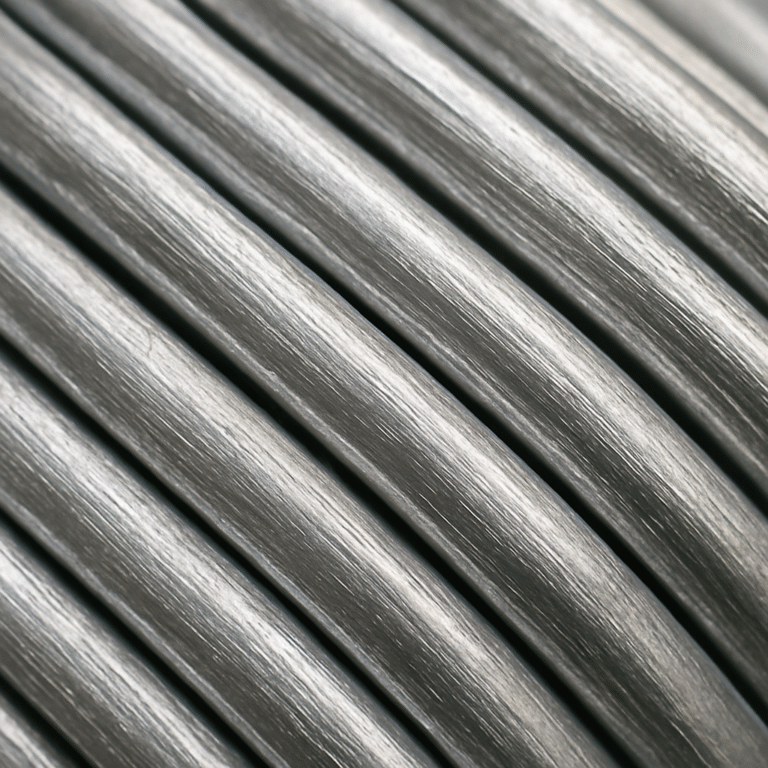

by Mariia Belinska (https://unsplash.com/@mashrooms21)

How Tough Is Alumina Ceramic? Understanding Alumina Toughness

Alumina ceramics are renowned for their toughness, which is rooted in their crystalline structure. The dense arrangement of atoms within the ceramic contributes significantly to its robustness. This structure allows the material to withstand considerable mechanical stress before failing.

Despite being inherently brittle, alumina ceramics possess remarkable crack resistance. This toughness makes it suitable for applications requiring reliable strength under stress. Components made from alumina can endure considerable loads without fracturing, which is critical in demanding industrial environments.

Several factors contribute to the toughness of alumina ceramics:

- Dense atomic structure

- High compressive strength

- Resistance to crack propagation

These factors combine to provide alumina with exceptional resilience. Therefore, it remains a preferred material for high-performance applications that demand toughness and durability. Its unique properties ensure that alumina continues to be indispensable in many industrial settings.

Comparing Alumina Ceramic to Other Ceramic Materials

Alumina ceramics stand out when compared to other ceramic materials due to their exceptional properties. While all ceramics are known for their hardness and resistance to high temperatures, alumina offers unique benefits that set it apart. Its high melting point and excellent electrical insulation make it a preferred choice for many applications.

In contrast, other ceramics like zirconia or silicon carbide may offer greater toughness or thermal shock resistance but lack the comprehensive durability profile of alumina. Alumina’s balance of strength, density, and heat resistance gives it an edge in many industrial processes where both toughness and consistency are essential.

Key distinctions between alumina ceramics and others include:

- Higher electrical insulation

- Superior chemical resistance

- Greater versatility in application

These qualities ensure alumina ceramics remain a top choice for engineers and designers globally.

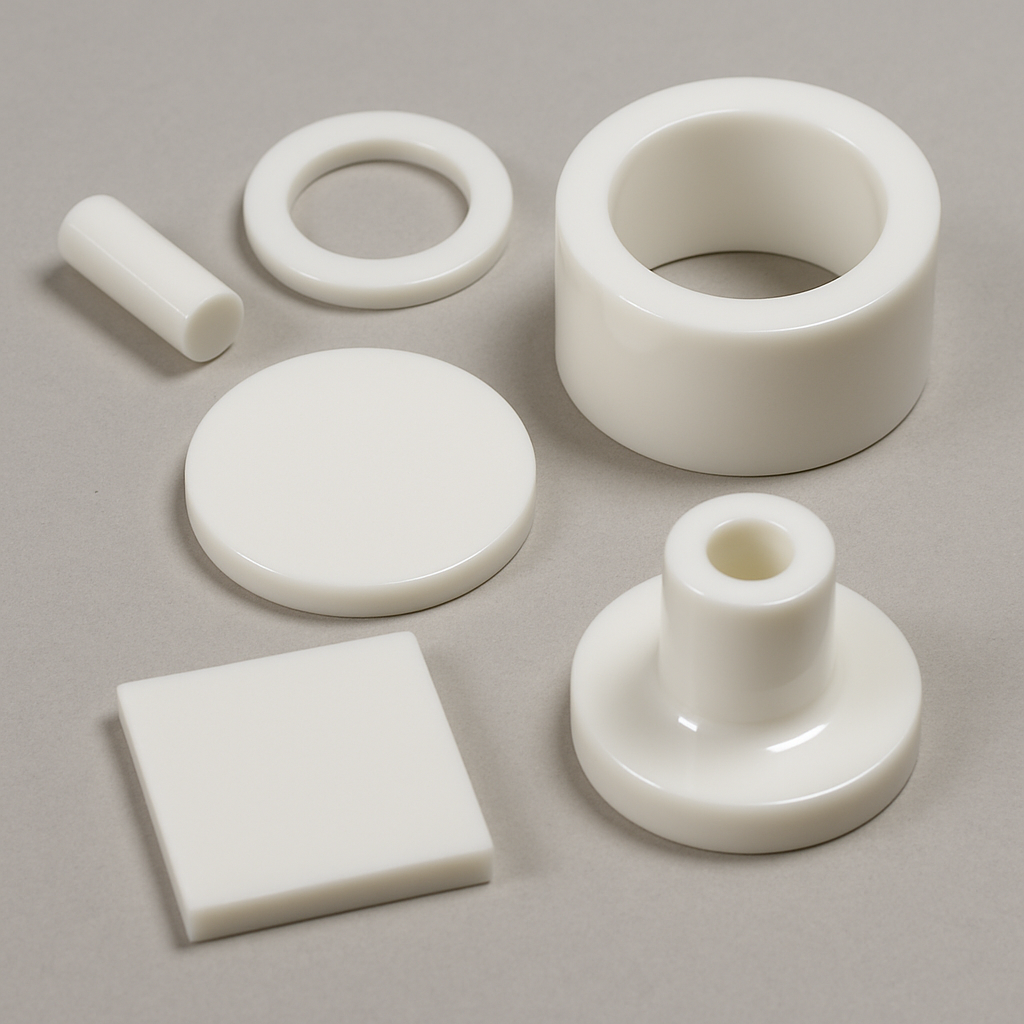

by Pew Nguyen (https://unsplash.com/@nguyentrungnguyen)

Common Applications: Where Durability Matters Most

Alumina ceramics are indispensable in industries where durability is crucial. Their resilience makes them ideal for environments that demand robust materials. High-stress applications such as machinery components and cutting tools rely on alumina for sustained performance.

In the electronics sector, alumina’s excellent electrical insulating properties make it perfect for substrates and components. This material’s ability to withstand high temperatures ensures the reliability of devices and circuits.

In addition, alumina ceramics are used in demanding environments like aerospace and defense, owing to their toughness and lightweight nature. Their adaptability across diverse applications is evident through their presence in:

- Medical implants

- Protective armor

- Thermal barriers

- Electronic substrates

- Laboratory equipment

Alumina’s versatility and exceptional properties enable it to meet the complex demands of modern industrial and technological applications.

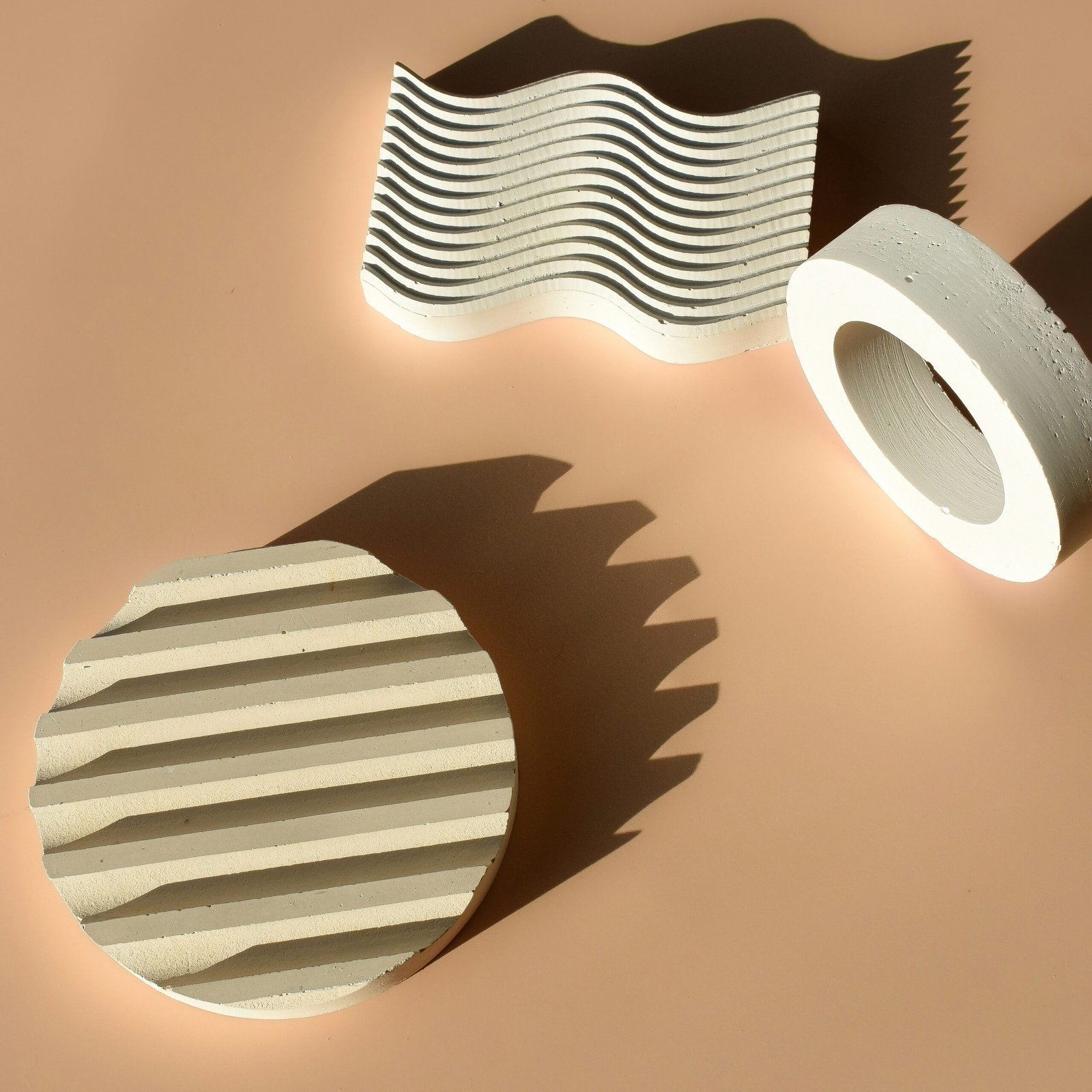

by Harper Sunday (https://unsplash.com/@harpersunday)

Factors That Affect the Longevity of Alumina Ceramics

The longevity of alumina ceramics is influenced by several critical factors. These elements can determine how well the material performs over time in various applications. Understanding these influences helps in choosing the right grade and application for alumina.

Key factors include:

- Environmental conditions: Exposure to chemicals and temperatures

- Mechanical stress: Pressure and impact it endures

- Quality of manufacturing: Precision in fabrication and sintering

Proper consideration of these factors is essential to maximize the lifespan of alumina ceramics. Tailoring the material to specific application conditions helps maintain its durability and performance across demanding environments.

Advances in Alumina Ceramic Technology

Recent advances in alumina ceramic technology have significantly enhanced its properties. These improvements have made the material more versatile in various industrial applications. Technological innovations continue to push the boundaries of what alumina ceramics can achieve.

Advances in technology include:

- Improved sintering techniques: Enhancing mechanical properties

- New composite formulations: Providing tailored solutions

- Development in processing methods: Offering better precision

These developments have led to alumina ceramics being more adaptable and better performing. As technology advances, alumina ceramic will continue to play a vital role in modern industrial solutions, reinforcing its position as a durable material choice.

Is Alumina Ceramic Durable? Final Thoughts

Alumina ceramic stands out as one of the most durable materials available. Its exceptional hardness, coupled with impressive wear resistance, ensures longevity in various environments.

While the material is brittle, it handles stress well due to its crystalline structure. These qualities make alumina ceramic a prime choice for applications demanding durability and reliability. In sum, when asked “is alumina ceramic durable?” the answer is a resounding yes.