Alumina dust is a common byproduct in many industries. It is also known as aluminum oxide dust.

This dust is prevalent in sectors like mining, manufacturing, and construction. Workers in these fields face potential exposure daily.

Understanding the risks associated with alumina dust is crucial. It can impact health and safety significantly.

Inhalation of alumina particles can lead to respiratory issues. Chronic bronchitis and lung fibrosis are potential concerns.

Alumina dust is often considered a nuisance. However, prolonged exposure can have serious health effects.

Safety measures are essential to minimize risks. Personal protective equipment and proper ventilation are key.

Regulatory guidelines help ensure safe exposure limits. Organizations like OSHA and NIOSH provide these standards.

Awareness and education are vital for workplace safety. Understanding alumina dangers can protect workers and communities.

What Is Alumina Dust?

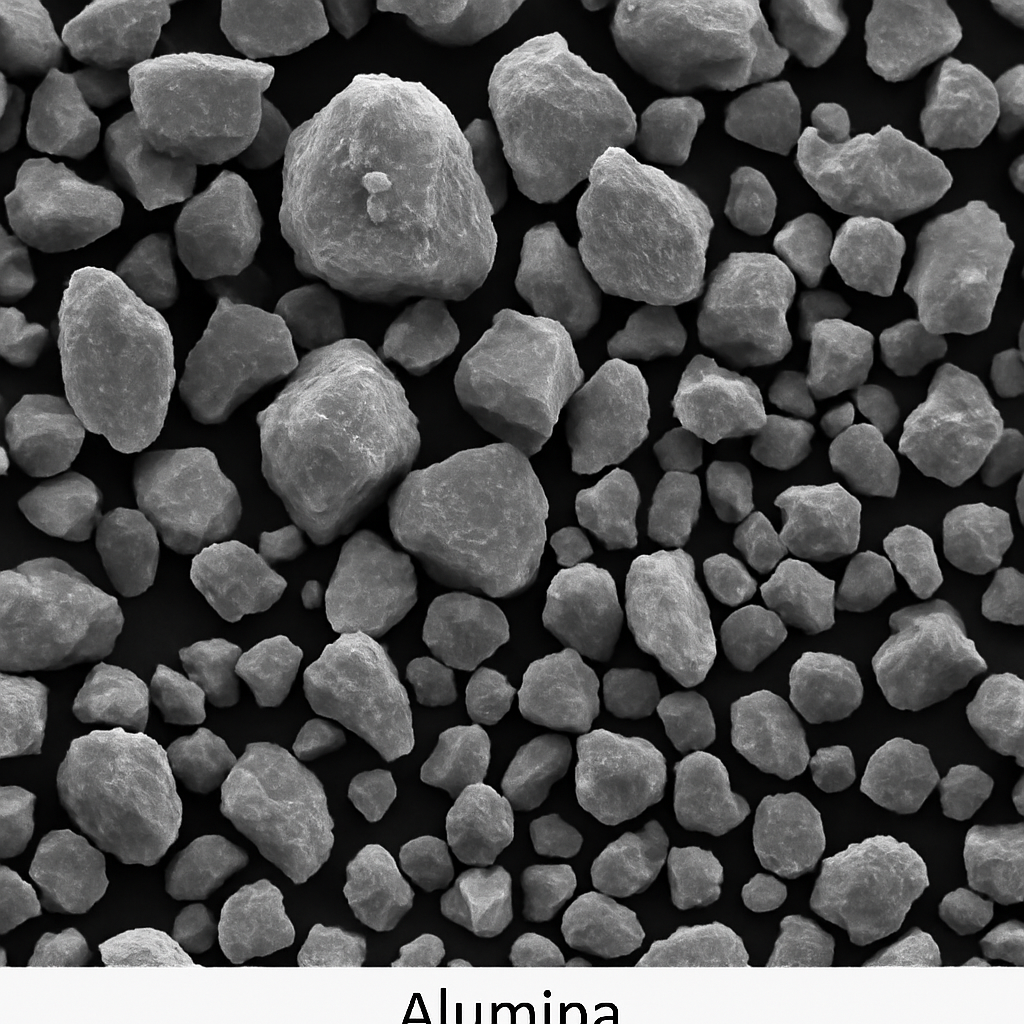

Alumina dust consists of fine particles of aluminum oxide. This compound is a key component in various industrial materials.

Commonly, alumina appears in dust, particles, or powder form. Its presence is widespread in industrial environments.

Characteristics of Alumina Dust:

- Fine and lightweight

- Often used in abrasive products

- Resistant to chemical reactions and heat

Alumina, or aluminum oxide, has a crystalline structure. This gives it stability and durability in many applications.

The alpha alumina form is especially stable. Industries use it in ceramics, polishing, and more.

Exposure to alumina dust can occur through several routes. Inhalation is the primary concern for workers.

Despite being considered a nuisance dust, alumina has significant risks. Proper management is essential to mitigate these dangers.

Sources and Industrial Uses of Alumina Dust

Alumina dust is commonly produced during industrial processes. These processes often involve the extraction or refinement of aluminum.

Bauxite mining stands as a primary source. During extraction, fine particles of alumina are released into the air.

Another major source is aluminum production. Smelting and refining activities generate significant alumina dust emissions.

In ceramics manufacturing, alumina serves as a critical component. The processing creates dust from grinding and shaping raw materials.

Industries Using Alumina Dust:

- Aluminum production

- Ceramics and glass

- Abrasive and polishing materials

- Electric insulation

Abrasive products often contain alumina powder. This increases the exposure risk in production and end-use environments.

In electric insulation, alumina’s resistance to heat and corrosion is essential. This use further broadens its industrial demand.

Each of these industries presents unique challenges. Workers must deal with dust control amid robust operations.

Proper containment measures in these settings are vital. They help to protect both workers and the environment.

Physical and Chemical Properties of Alumina Particles

Alumina particles, known scientifically as aluminum oxide, exhibit unique characteristics. These properties play a crucial role in their industrial applications.

by Chi-Feng Li (https://unsplash.com/@chiffoncake12)

Key Properties of Alumina Particles:

- High melting point

- Chemical stability

- Hardness

- Electrical insulation

Alumina’s high melting point stands at around 2,072 degrees Celsius. This makes it suitable for high-temperature environments.

Chemically, alumina remains stable even when exposed to acids and bases. This stability is essential for various industrial processes.

The hardness of alumina is another notable feature. It ranks high on the Mohs scale, just below diamonds, which makes it ideal for abrasive applications.

As an electrical insulator, alumina is vital in electronics and telecommunication. It prevents electrical discharge, thus ensuring the safety and longevity of devices.

The microscopic structure of alumina determines its reactivity and behavior. Alpha alumina, a dense form, is especially resistant to chemical attacks.

Such properties not only determine usability but also the safety measures necessary during handling. Workers should be aware of alumina’s chemical and physical traits to manage risks effectively. Understanding these attributes helps devise better safety protocols in workplaces using alumina.

How Exposure to Alumina Dust Occurs

Exposure to alumina dust can happen in various ways. People working in industries face the highest risks.

by Wolfgang Hasselmann (https://unsplash.com/@wolfgang_hasselmann)

Inhalation is the most common route of exposure. Tiny alumina particles can become airborne, easily entering the respiratory system.

Skin contact with alumina dust also poses risks. While less severe than inhalation, it can lead to irritation or dermatitis.

Common Routes of Alumina Dust Exposure:

- Inhalation

- Skin contact

- Ingestion

Exposure might also occur through accidental ingestion. Dust can settle on food or personal items, leading to possible ingestion.

Certain industries, like mining and ceramics, have higher exposure levels. Dust can accumulate in these workplaces, affecting both workers and equipment.

It’s important to note that the size of alumina particles influences exposure risks. Smaller particles can penetrate deeper into the lungs, increasing health concerns.

Employers must assess and mitigate these exposure routes. Implementing controls and safety measures reduces the potential for harm. Monitoring air quality and ensuring clean workspaces help prevent dust-related issues. The goal is to protect workers and maintain a safe industrial environment.

Health Risks and Alumina Dangers

Exposure to alumina dust presents several health risks. Although considered a nuisance dust, prolonged contact can lead to serious conditions.

by Wolfgang Hasselmann (https://unsplash.com/@wolfgang_hasselmann)

Inhalation of aluminum oxide dust is particularly concerning. It can cause respiratory problems like chronic bronchitis and lung fibrosis.

Workers exposed to high levels may experience persistent coughing. Shortness of breath is another common symptom among those frequently exposed.

Symptoms of Alumina Dust Exposure:

- Coughing and throat irritation

- Shortness of breath

- Skin irritation or rashes

The effects of alumina particles on the lungs are significant. These particles can infiltrate deep into lung tissue, causing damage over time.

Besides respiratory issues, skin exposure can lead to dermatitis. Irritation and redness occur when dust is not properly managed.

Long-Term Health Consequences:

- Chronic respiratory diseases

- Potential for lung damage

- Dermatological conditions

While alumina dust is not labeled as a carcinogen, its potential to cause lung harm is still a concern. Workers in high-exposure areas must be vigilant.

Health monitoring for workers is a critical safety measure. Regular check-ups can help detect early signs of overexposure.

Employers need to ensure a safe environment by lowering dust levels. Implementing dust control systems is essential to protect worker health. Collaboration with health professionals can enhance workplace safety measures.

Understanding the associated risks of alumina dust is crucial. It helps in developing effective preventive strategies and safety protocols.

Prompt action in addressing health concerns can minimize risks. A well-informed workforce is less likely to suffer from alumina dangers. Employers play an essential role in promoting safety and health awareness.

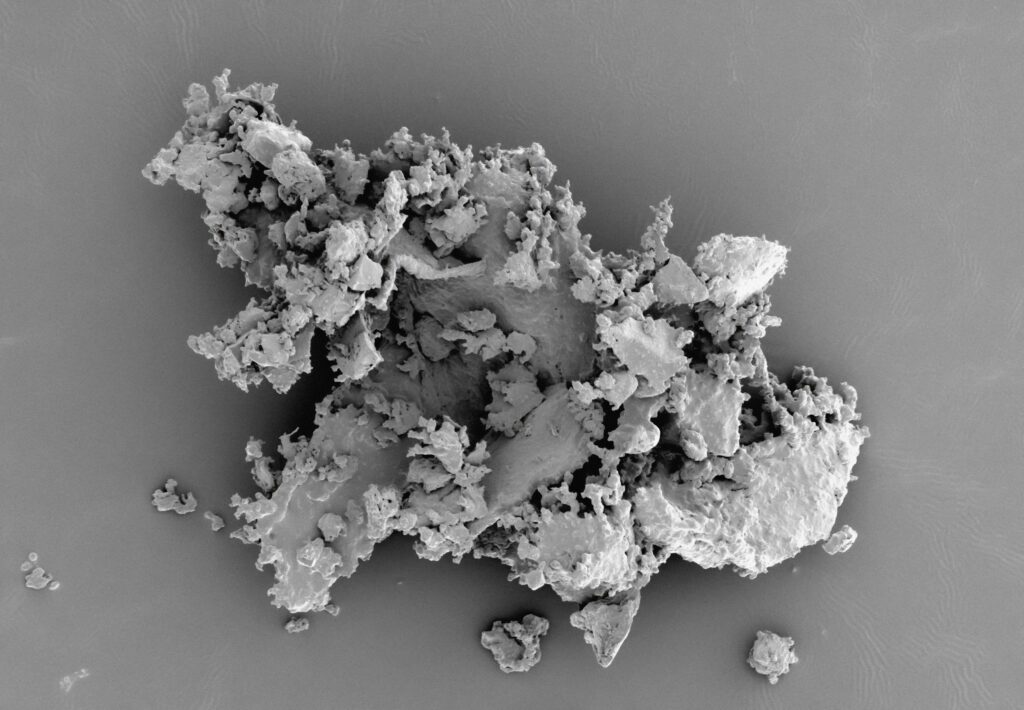

Environmental Impact of Alumina Dust

Alumina dust not only affects human health but also poses environmental challenges. If not managed correctly, it can contribute to air pollution and broader ecological issues.

by National Institute of Allergy and Infectious Diseases (https://unsplash.com/@niaid)

Alumina particles can travel and settle on vegetation, disrupting plant growth. They may coat leaves, reducing photosynthesis and impacting local flora.

Water bodies near industrial sites are at risk if alumina dust is not contained. Particles can enter waterways, affecting aquatic ecosystems and water quality.

Potential Environmental Issues:

- Air pollution from airborne particles

- Contamination of local water sources

- Damage to plant life and ecosystems

The physical properties of alumina dust, such as its fine texture, allow it to remain suspended in the air. This characteristic increases its range of impact.

Regulations aim to limit environmental exposure to alumina dust. These guidelines ensure that industries implement effective dust management systems.

Effective dust suppression and containment can mitigate environmental impacts. Strategic measures can protect ecosystems and maintain biodiversity.

Understanding the environmental risks is essential for communities near industrial operations. Public awareness and proactive measures can further enhance ecological safety. Industry compliance with environmental standards plays a crucial role in sustainable practices.

Monitoring alumina dust levels in the environment helps identify problem areas. Regular assessment can lead to timely interventions, minimizing harm to nature.

Regulatory Guidelines and Exposure Limits

Regulatory guidelines help protect workers from the risks associated with alumina dust. These standards are crucial for maintaining safe levels in the workplace.

by Arturo Añez (https://unsplash.com/@americanaez225)

Organizations like OSHA and NIOSH establish exposure limits to safeguard health. These limits are based on scientific research and expert recommendations.

Key Regulatory Aspects:

- Defined safe exposure levels

- Guidelines for monitoring air quality

- Requirements for dust control measures

Exposure limits aim to prevent adverse health effects. They consider factors like dust concentration and duration of exposure in industrial settings.

Companies must implement strategies to comply with these guidelines. This includes regular monitoring of air quality and use of proper ventilation systems.

Non-compliance with these regulations can lead to severe penalties. Consequences may include fines or operational restrictions for the offending companies.

Regular updates to the guidelines ensure they reflect current research. Continuous review helps to accommodate emerging data about alumina dust hazards.

Understanding and adhering to these standards is essential for workplace safety. Employers and employees need to collaborate to achieve compliance and ensure a healthy work environment. Leveraging these guidelines enhances safety, aligns with legal standards, and protects public health.

Workplace Safety Measures and Best Practices

Implementing effective safety measures is crucial to minimize the risks of alumina dust. Protecting workers involves a multifaceted approach tailored to specific industrial processes.

by Bermix Studio (https://unsplash.com/@bermixstudio)

First, assessing the workplace environment is key. Conducting a thorough risk assessment identifies potential sources of exposure.

Control measures should be prioritized based on assessed risks. Engineering controls, like local exhaust ventilation, can significantly reduce airborne dust.

Engineering Controls:

- Install local exhaust systems

- Use wet methods to suppress dust

- Maintain air filtration systems

Administrative controls complement engineering efforts. These include scheduling regular maintenance and implementing standard operating procedures (SOPs) for handling materials.

Administrative Measures:

- Establish clean-up schedules

- Limit worker exposure times

- Enforce decontamination protocols

Training programs reinforce safety policies. Workers need clear instructions on recognizing hazards and wearing proper protective equipment.

Maintaining a clean workspace minimizes secondary dust exposure. Regular cleaning prevents dust accumulation on surfaces and equipment.

Emergency response plans should be in place. Quick action protocols are essential if exposure incidents occur or dust levels spike unexpectedly.

Managers and safety officers should regularly review safety practices. Continuous evaluation ensures that safety measures adapt to changes in processes or regulations.

Combining these strategies fosters a safer working environment. A proactive approach leads to fewer health issues and enhances overall productivity.

Personal Protective Equipment (PPE) for Alumina Dust

Personal protective equipment (PPE) is essential in managing exposure to alumina dust. It acts as the last line of defense for workers’ safety.

by Scentll Co (https://unsplash.com/@scentll)

Respirators are critical for protecting respiratory health. Selecting the right respirator depends on the concentration and particle size of the dust.

Protective clothing minimizes skin contact. Coveralls, gloves, and goggles should be made of materials resistant to dust penetration.

Essential PPE for Alumina Dust:

- NIOSH-approved respirators

- Dust-resistant coveralls

- Protective gloves

- Safety goggles

Regular maintenance and inspection of PPE are necessary. Equipment should be free of damage and fit properly to ensure maximum protection.

Providing training on correct PPE use is vital. Workers must understand how to wear, remove, and care for their equipment effectively.

By emphasizing proper PPE, employers can significantly reduce health risks associated with alumina dust exposure. This practice ensures a safer, healthier workplace for all employees.

Monitoring, Detection, and Air Quality Control

Effective monitoring of alumina dust is crucial for workplace safety. It helps identify exposure levels and assess risk.

by Alex Ringer (https://unsplash.com/@alexringer)

Advanced detection tools can measure particle concentrations in real-time. This technology allows for prompt corrective actions.

Consistent air quality checks ensure compliance with safety regulations. These assessments prevent dangerous exposure levels.

Key Techniques for Air Quality Control:

- Real-time air sampling tools

- Regular air quality assessments

- Installation of air filtration systems

Employers need to invest in high-quality air monitoring systems. Proper installation and maintenance of these systems are vital.

Collaboration between safety officers and workers is essential in maintaining optimal air conditions. This partnership supports a proactive safety culture.

Air quality control strategies are essential for minimizing risks associated with alumina dust. Keeping the workplace air clean protects workers’ health.

Training, Education, and Worker Awareness

Educating workers about alumina dust risks is vital for safety. Proper training ensures workers understand how to handle exposure effectively.

by Yk K (https://unsplash.com/@koneca)

Awareness programs focus on the dangers of alumina particles. These initiatives empower workers to recognize and mitigate risks.

Regular seminars and workshops keep employees informed about safety updates. These events reinforce the importance of following safety protocols.

Essential Training Topics:

- Identifying symptoms of dust exposure

- Proper use of personal protective equipment (PPE)

- Emergency response procedures

Employers are responsible for providing comprehensive training resources. These materials should be accessible and updated regularly.

Employee participation in training programs encourages a culture of safety awareness. An informed workforce can better protect themselves and others.

Real-life case studies can also be incorporated into training. They provide valuable insights and enhance learning outcomes.

Overall, continuous education equips workers to maintain a safe working environment. Keeping safety at the forefront ensures long-term health and productivity.

Innovations and Future Directions in Alumina Dust Management

Advancements in technology play a crucial role in managing alumina dust. New methods are being developed to enhance dust control in industrial settings.

by Cemrecan Yurtman (https://unsplash.com/@cmrcn_)

Innovative filtration systems capture finer alumina particles more efficiently. These systems reduce airborne dust and improve air quality significantly.

Emerging research continues to explore novel approaches. These include eco-friendly techniques that minimize environmental impact while ensuring safety.

Key Innovations in Alumina Dust Management:

- High-efficiency particulate filters

- Advanced dust suppression systems

- Environmentally friendly dust control methods

Smart technology and automation streamline dust monitoring processes. Real-time data helps industries to promptly adjust safety measures.

Future innovations aim to balance industrial productivity with health concerns. The continued development in this field promises safer work environments.

Collaboration among researchers, industries, and governments fosters new solutions. This teamwork is vital in overcoming the challenges of alumina dust management.

Overall, embracing innovation leads to a healthier, more efficient industrial landscape. As technology evolves, so does the potential for improved safety measures.

Frequently Asked Questions About Alumina Dust

When it comes to alumina dust, many questions arise. Understanding its risks is crucial for safety.

One common query involves health impacts. Prolonged exposure can lead to respiratory issues and skin irritation.

Frequently Asked Questions:

- What is alumina dust?

- How can exposure be minimized?

- What are the health risks of inhalation?

Questions about minimizing exposure are prevalent, too. Effective methods include using PPE and ensuring proper ventilation.

Lastly, people are concerned about environmental effects. Proper management helps mitigate air pollution caused by alumina dust. Addressing these concerns is vital for worker safety and environmental protection.

Conclusion: Balancing Industry and Safety

Industrial use of alumina dust is crucial for various sectors. Yet, its health impacts cannot be ignored.

Employers must prioritize worker safety. Implementing effective dust control measures is essential to mitigate risks.

Education and training play vital roles. Workers need to recognize the signs of overexposure to alumina dust.

Collaboration is key in achieving a safe environment. Industries, regulators, and health experts should work together. Continuous research and innovation will drive improvements in safety practices, ensuring a balanced approach between industrial growth and the well-being of workers and communities.