White fused alumina is a remarkable material with diverse applications. It is a high-purity synthetic product derived from alumina powder.

This material is created by fusing alumina in an electric arc furnace. The process occurs at temperatures exceeding 2000°C.

White fused alumina is known for its hardness and toughness. It also boasts a high melting point, making it ideal for demanding uses.

Industries value it for its abrasive qualities. It can cut, grind, and polish hard surfaces with ease.

Its high thermal stability makes it perfect for refractory applications. It withstands extreme temperatures and resists corrosion.

White corundum, another name for this material, highlights its crystalline structure. This structure is similar to natural corundum.

The material’s purity is crucial in sensitive industries. It is used in medical, aerospace, and electronic applications.

White fused alumina is versatile and environmentally friendly. It can be recycled, reducing industrial waste.

What is White Fused Alumina?

White fused alumina is a synthetic material prized for its purity and performance. It originates from alumina powder, which is a finely ground form of aluminum oxide.

Produced using an electric arc furnace, the manufacturing process involves fusing alumina at high temperatures. This process results in a hard and chemically stable product.

White fused alumina is characterized by several key properties. It exhibits a distinct crystalline structure akin to natural corundum. This structure contributes to its exceptional hardness and durability.

The versatility of white fused alumina is significant. It can be used for a variety of industrial and commercial applications. Common usage areas include surface treatment and high-temperature environments.

Some key features of white fused alumina include:

- High purity and low levels of iron contamination

- Extremely hard and durable material

- Excellent thermal and electrical insulating properties

White corundum’s composition also plays a crucial role in its industrial utility. It is preferred for use in products where contamination must be minimal, such as in the medical field.

Recognized as a reliable choice for precision applications, this material is essential in numerous sectors. Its adaptability ensures it remains a staple across industries, from electronics to construction.

White fused alumina’s ability to perform under demanding conditions is unmatched. It supports increased efficiency in abrasive and refractory applications, contributing to its widespread appeal.

Production Process of White Fused Alumina

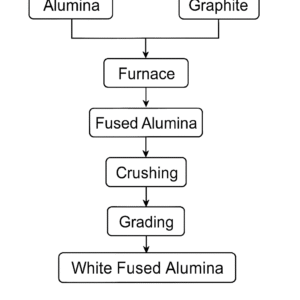

The production of white fused alumina involves a highly controlled process. It begins with carefully selected alumina powder, which ensures the highest quality standards.

In the next step, the alumina powder is introduced into an electric arc furnace. The furnace operates at temperatures exceeding 2000°C, fusing the powder into a molten state.

This high-temperature environment is crucial. It initiates the physical changes needed to form white corundum crystals. Once fused, the molten alumina cools gradually to form solid, crystalline blocks.

The cooling process is meticulously controlled. It ensures that the structural integrity and purity of the material are maintained. The resulting crystalline blocks are then crushed and sieved into desired sizes.

The production process of white fused alumina can be summarized as follows:

- Selection and preparation of high-purity alumina powder

- Fusing in an electric arc furnace at high temperatures

- Controlled cooling to form crystalline structures

- Crushing and sieving to produce various grit sizes

The quality of white fused alumina is consistently high due to these precise production steps. As a result, the material is suitable for a wide range of industrial applications.

White fused alumina’s production is both an art and a science. The careful balance of temperature, time, and material properties ensures a top-tier final product every time.

Key Properties of White Fused Alumina

White fused alumina is renowned for its exceptional hardness and toughness. These properties make it highly effective in abrasive applications. It efficiently cuts and polishes hard surfaces with precision.

This material’s high melting point is a major advantage. It withstands extreme temperatures, making it ideal for high-temperature environments. This property ensures its stability in challenging conditions.

Another notable characteristic is its chemical inertness. This allows white fused alumina to resist chemical reactions even under harsh conditions. Thus, it is perfect for applications involving chemical processing.

White corundum, as it is also known, exhibits high thermal stability. This stability ensures minimal thermal expansion, enhancing its reliability in refractory applications. It maintains integrity even in repeated thermal cycles.

Here are some key properties of white fused alumina:

- High hardness and toughness

- High melting point over 2000°C

- Chemical inertness

- High thermal stability

- Low thermal expansion

by Jeroen van de Water (https://unsplash.com/@joenevdw)

Furthermore, the crystalline structure of white alumina provides consistent performance. Its robust nature makes it suitable for various industrial uses. In addition, its purity is critical in applications demanding zero contamination.

The combination of these properties makes white fused alumina a versatile material. It offers reliability and durability across different sectors. Industries leveraging its properties benefit from increased efficiency and longevity in their applications.

Comparison: White Fused Alumina vs. Other Abrasive Materials

White fused alumina stands out among abrasive materials due to its high purity. This trait is unmatched by other substances used in similar applications. Its minimal contamination is crucial for precision industries like aerospace.

Compared to silicon carbide, white alumina offers superior thermal stability. While silicon carbide may break down under high temperatures, white fused alumina retains its structure. This makes it a preferred choice for high-temperature environments.

Garnet and other natural abrasives tend to have inconsistencies in hardness. In contrast, white corundum provides reliable performance with uniform properties. This consistency is vital for predictable results in grinding and polishing.

Other materials, such as emery, lack the durability found in white fused alumina. Durability ensures prolonged use, reducing replacement frequency and costs. It’s an economically sound option for long-term industrial operations.

Below are some key distinctions:

- High purity compared to other abrasives

- Superior thermal stability over silicon carbide

- Uniform properties, unlike natural abrasives

- Greater durability than emery

by Waldemar Brandt (https://unsplash.com/@waldemarbrandt67w)

These qualities establish white fused alumina as a leading abrasive material. Industries that require precision, high heat tolerance, and longevity favor it. Its adaptable nature supports a broad array of applications across diverse fields.

Benefits of Using White Fused Alumina

White fused alumina, or white corundum, offers numerous advantages in industrial and precision applications. This material’s supreme hardness allows it to cut, grind, and polish hard surfaces effectively. The sharp edges provide outstanding abrasive action essential in many processes.

Another significant benefit is its high melting point, resisting extreme temperatures with ease. This makes white fused alumina ideal for refractories where heat resistance is critical. Its reliability in these challenging conditions extends the lifespan of kilns and furnaces.

Purity is a paramount characteristic of this fused alumina. The material contains minimal impurities, which reduces contamination risks in sensitive applications. Industries such as medical and aerospace benefit from this aspect due to their stringent purity requirements.

This alumina’s chemical stability contributes to its versatility. It withstands corrosion, making it suitable for chemical processing environments. The inert nature helps maintain structural integrity, ensuring consistent performance in reactive atmospheres.

Environmental considerations are increasingly important, and white fused alumina excels here too. Its recyclable nature makes it an eco-friendly option, reducing waste. This aligns with sustainable practices and lowers the environmental impact of industrial operations.

Below is a summary of the benefits:

- High hardness for effective abrasion

- Extreme temperature resistance

- Purity for minimal contamination

- Chemical stability and corrosion resistance

- Recyclable and eco-friendly

by Pawel Czerwinski (https://unsplash.com/@pawel_czerwinski)

In conclusion, white fused alumina provides high performance with economic benefits. Its unique properties make it indispensable across diverse industries. These attributes drive its continued use in numerous innovative applications.

Major Industrial Applications

White fused alumina is a highly versatile material with applications spanning several industries. Its unique properties, such as hardness and purity, are especially valuable in specific sectors.

In the abrasives industry, white fused alumina is a staple choice for producing grinding and cutting tools. The material’s durability and high cutting efficiency make it an optimal option.

The refractory industry heavily relies on white fused alumina because of its superior thermal resistance. Refractory materials face extreme temperatures, and alumina ensures longevity under such conditions.

Surface treatment processes, including polishing and blasting, also benefit from alumina’s abrasive qualities. It excels at removing unwanted coatings and finishes while preparing surfaces for further treatment.

The electronics and semiconductor manufacturing industries utilize white corundum for its high purity and stability. These characteristics are critical in producing sensitive components where impurities can affect performance.

Medical and aerospace fields demand materials with minimal contamination risk, and white alumina fits the bill. Its inertness and purity ensure top performance in these demanding applications.

White fused alumina’s environmental friendliness is another draw, making it an attractive choice for eco-conscious industries. Its recyclability reduces waste and aligns with green initiatives.

Below are some key applications for white fused alumina:

- Abrasives

- Refractories

- Surface treatment

- Electronics manufacturing

- Medical and aerospace

by Rick Rothenberg (https://unsplash.com/@rick_rothenberg)

Abrasives Industry

The abrasives industry uses white fused alumina to manufacture a wide variety of tools. These include grinding wheels, sandpaper, and polishing stones.

White alumina is favored for its consistent quality and hardness. These properties result in effective material removal and long-lasting abrasive products.

The specific grit size of fused alumina can be customized for different tasks. This adaptability allows manufacturers to tailor products for specific applications.

Furthermore, its low impurity level ensures uniformity in abrasive action. The result is high-quality finishes for various materials, from metals to glass.

Key abrasive products using white fused alumina include:

- Grinding wheels

- Sandpaper

- Polishing compounds

by Deng Xiang (https://unsplash.com/@dengxiangs)

Refractory Industry

Refractory applications demand materials that withstand extreme heat and mechanical stress. White fused alumina meets these requirements with excellence.

The material’s high melting point and thermal stability ensure performance under intense temperatures. As a result, white alumina is an ideal component in linings for kilns, furnaces, and incinerators.

Additionally, its resistance to corrosion and chemical reactions extends the life of refractory products. This makes it a cost-effective choice for demanding environments.

White alumina also contributes to improved energy efficiency. It effectively insulates thermal equipment, reducing heat loss.

Applications in the refractory industry include:

- Kiln linings

- Furnace bricks

- Incinerator components

by Stef Westheim (https://unsplash.com/@topdata)

Surface Treatment and Blasting

In surface treatment, achieving a smooth finish is paramount. White fused alumina excels in lapping and polishing, offering fine control for delicate operations.

The material’s hardness is key to its effectiveness in blasting applications. It can remove rust, scale, and old coatings without damaging the underlying surface.

White alumina’s consistent particle size allows for precise blasting. This attribute is essential in industries like automotive and construction where surface quality is critical.

Moreover, its purity means it won’t contaminate surfaces. This feature is crucial when preparing metals and ceramics for further processing.

Common surface treatment uses include:

- Lapping and polishing

- Rust and scale removal

- Surface preparation

by piotr sawejko (https://unsplash.com/@piotrsaw)

Electronics and Semiconductor Manufacturing

Electronics and semiconductor manufacturers seek materials with high purity and precision. White fused alumina rises to the challenge, being a crucial component in this field.

Its stable structure supports the production of wafers and other semiconductor components. Any impurity could disrupt the function of these sensitive elements.

The material’s chemical inertness ensures no adverse reactions occur during production. This stability is paramount in maintaining efficiency and yield in manufacturing.

Furthermore, white alumina’s hardness aids in precision cleaning of delicate electronic parts. This ensures the longevity and performance of finished products.

Uses in electronics manufacturing include:

- Wafer production

- Component polishing

- Precision cleaning

by Mastars (https://unsplash.com/@mastars)

Medical and Aerospace Applications

In the medical field, materials need to meet strict safety standards. White fused alumina, with its exceptional purity, is highly suited for these applications.

Its inertness means it can be used in medical devices with no risk of causing adverse reactions. This is crucial for applications involving direct contact with sensitive tissues.

For aerospace uses, white alumina offers resilience in extreme environments. Its stability under thermal stress is invaluable for components exposed to high temperatures.

In both sectors, the material’s reliability ensures safe and efficient performance. This results in increased trust and widespread adoption.

Key applications include:

- Medical implants and devices

- Aerospace parts

- Instrumentation components

by Markus Winkler (https://unsplash.com/@markuswinkler)

Environmental Impact and Sustainability

White fused alumina stands out for its environmentally friendly aspects. It can be recycled, offering a sustainable solution for many industries. This ability to be reused helps to minimize waste and reduce the overall environmental footprint.

Furthermore, its high efficiency in applications means less raw material consumption over time. Products made with white fused alumina often have a longer lifespan. This durability contributes to a decrease in the frequency of replacements and, consequently, less waste.

Industries increasingly value materials that align with green initiatives. The recyclability of white alumina makes it a favored choice for eco-conscious companies. By choosing recycled fused alumina, industries can support sustainability goals while maintaining high performance.

Key environmental benefits of white fused alumina include:

- Recyclability

- Reduced material waste

- Contribution to sustainability goals

by Aitor Olaskoaga (https://unsplash.com/@oilasko)

How to Select the Right White Fused Alumina for Your Application

Choosing the right type of white fused alumina is crucial for achieving optimal results. Consider the specific requirements of your project to make an informed decision. Different applications may demand varying attributes, such as grit size and purity.

First, assess the surface or material that needs treatment. Determine whether you need coarse or fine alumina powder based on the desired finish. This decision impacts the smoothness and quality of the end result.

Next, factor in the operating environment, especially temperature extremes. High-temperature applications call for materials with superior thermal stability. White fused alumina refractory is often the preferred choice in such scenarios.

Key considerations when selecting white fused alumina:

- Desired surface finish

- Operating temperature conditions

- Application-specific requirements

Selecting the right white alumina helps to enhance efficiency and cost-effectiveness. Making an informed choice ensures that the material’s properties align with your specific needs.

by Annie Spratt (https://unsplash.com/@anniespratt)

Frequently Asked Questions about White Fused Alumina

What is white fused alumina?

White fused alumina, also known as white corundum, is a synthetic material known for its hardness and purity. It is extensively used in various industrial applications.

How is white fused alumina produced?

It is manufactured by fusing alumina powder in an electric arc furnace at temperatures above 2000°C. This process results in its high purity and crystalline structure.

What are the primary uses of white fused alumina?

It is commonly utilized for abrasive, refractory, and surface treatment applications. The material’s versatility makes it suitable for a wide range of industries.

Are there environmental concerns with using white fused alumina?

White fused alumina is eco-friendly and recyclable. Its use can help reduce waste and improve sustainability in industrial processes.

Conclusion

White fused alumina stands out as a versatile and reliable material across various industries. Its impressive hardness, high melting point, and chemical inertness make it indispensable. Industries ranging from abrasives to electronics benefit immensely from its unique properties.

The sustainable nature of white fused alumina adds to its appeal. As companies seek eco-friendly solutions, this recyclable material offers a reduced environmental footprint. Its applications in cutting, grinding, and polishing highlight its role in enhancing product quality.

Selecting the right type of white fused alumina is crucial for achieving desired outcomes. Understanding its properties and compatibility with specific applications ensures optimal performance. This selection process can significantly enhance efficiency and cost-effectiveness.

Overall, white fused alumina’s consistent performance and adaptability position it as a leading choice for industries worldwide. Its broad array of applications combined with its durability solidifies its status as an essential industrial resource.