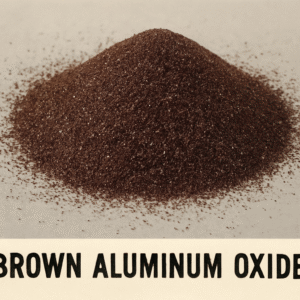

Brown aluminum oxide, also known as brown fused aluminum oxide, is a type of abrasive material made from bauxite. It is created through a fusion process that involves melting bauxite in an electric arc furnace. The result is a crystalline material that is extremely tough and durable, making it ideal for abrasive applications.

The Manufacturing Process

The production of brown aluminum oxide begins with the extraction of bauxite, a naturally occurring mineral rich in aluminum. The bauxite is then subjected to a high-temperature fusion process in an electric arc furnace, reaching temperatures up to 2000 degrees Celsius. This intense heat causes the bauxite to melt and form a glass-like substance, which is then cooled and crystallized into brown aluminum oxide grains.

Characteristics and Composition

Brown aluminum oxide is primarily composed of aluminum oxide (Al2O3), but it also contains traces of other elements such as titanium dioxide and iron oxide. These impurities contribute to its unique color and enhance its abrasive properties. The presence of these additional elements gives brown aluminum oxide its characteristic toughness and makes it suitable for heavy-duty applications.

Variants and Grades

There are various grades of brown aluminum oxide available, each with different levels of purity and grit size. The purity of the material affects its performance and suitability for specific applications. Higher purity grades offer enhanced cutting capabilities and are preferred for precision tasks, while lower purity grades are used for more general-purpose applications.

Properties of Brown Aluminum Oxide

Brown aluminum oxide is characterized by its high density, toughness, and ability to retain its form under high-pressure conditions. These properties make it one of the most effective abrasives available. Additionally, it has a high melting point, which allows it to withstand extreme temperatures without losing its structural integrity.

High Hardness

The hardness of brown aluminum oxide is one of its most defining properties. On the Mohs scale, it ranks around 9, just below diamond, which makes it capable of cutting through the hardest materials. This hardness is crucial for applications that require aggressive material removal or surface preparation.

Thermal Stability

Brown aluminum oxide’s high melting point, exceeding 2000 degrees Celsius, means it can endure extreme temperatures encountered in industrial processes without degrading. This thermal stability is vital for applications involving high heat, such as refractory materials and certain types of metalworking.

Chemical Resistance

In addition to its physical properties, brown aluminum oxide exhibits excellent chemical resistance. It is inert to most acids and alkalis, which makes it suitable for use in environments where chemical exposure is a concern. This resistance extends its lifespan and maintains its effectiveness in harsh conditions.

Benefits of Brown Aluminum Oxide

Brown aluminum oxide offers several benefits that make it a preferred choice for many applications:

Durability and Strength

One of the primary benefits of brown aluminum oxide is its durability. It is one of the hardest materials available, which allows it to cut through tough surfaces with ease. Its strength also ensures that it can withstand repeated use without degrading, making it a cost-effective choice for industrial applications.

Cost-Effectiveness

The longevity of brown aluminum oxide contributes to its cost-effectiveness. Since it maintains its abrasive properties over multiple uses, it reduces the frequency of replacement and the associated costs. This durability translates to lower operational expenses, particularly in high-volume production environments.

Consistent Performance

Another advantage of brown aluminum oxide is its ability to deliver consistent performance. Its uniform grain size and shape ensure that it provides a steady abrasive action, which is crucial for achieving uniform results in surface finishing and material removal processes.

Versatility

Brown aluminum oxide is incredibly versatile. It can be used in a variety of applications ranging from blasting to surface preparation and even in the production of grinding wheels. Its ability to adapt to different tasks makes it a valuable asset in various industries.

Wide Range of Applications

The versatility of brown aluminum oxide extends to a wide range of industries, from automotive to aerospace. It is used in applications such as sandblasting, grinding, and polishing, demonstrating its adaptability to different processes and requirements.

Compatibility with Other Materials

Brown aluminum oxide can be used on a variety of materials, including metals, glass, ceramics, and plastics. This compatibility makes it a preferred choice for industries that deal with diverse materials, as it can be applied without the need for material-specific abrasives.

Eco-Friendly

Compared to other abrasive materials, brown aluminum oxide is considered more environmentally friendly. It can be recycled and reused multiple times, reducing the need for continuous extraction of raw materials. This not only helps in conserving natural resources but also minimizes waste.

Recycling Benefits

The recyclability of brown aluminum oxide contributes to sustainable manufacturing practices. By reusing the abrasive material, industries can significantly reduce their environmental footprint, making it an attractive option for companies committed to eco-friendly operations.

Reduced Environmental Impact

Additionally, the use of brown aluminum oxide minimizes the environmental impact associated with mining and processing new raw materials. Its reusability reduces the demand for virgin resources, which aligns with global efforts to promote sustainable development and resource conservation.

Uses of Brown Aluminum Oxide

Brown aluminum oxide is utilized in numerous industries due to its superior properties. Here are some of the common uses:

Abrasive Blasting

One of the most common uses of brown aluminum oxide is in abrasive blasting. Its hardness and angular shape make it ideal for removing paint, rust, and other surface contaminants. It is widely used in preparing surfaces for painting or coating, ensuring a clean and smooth finish.

Surface Finishing

In abrasive blasting, brown aluminum oxide is employed to achieve specific surface finishes, ranging from rough to smooth, depending on the desired outcome. Its efficiency in cleaning and preparing surfaces ensures optimal adhesion for subsequent coatings or treatments.

Industrial Cleaning

Beyond surface preparation, brown aluminum oxide is used in industrial cleaning applications. It effectively removes stubborn deposits from equipment and machinery, enhancing operational efficiency and extending the lifespan of industrial assets.

Grinding and Polishing

by Brian Kairuz (https://unsplash.com/@briankairuz)

Brown aluminum oxide is also used in the manufacturing of grinding wheels and other polishing tools. Its toughness allows it to grind down hard materials like steel and iron effectively. In the polishing industry, it is used to achieve a high-gloss finish on metals and other hard surfaces.

Metalworking Applications

In metalworking, brown aluminum oxide is indispensable for tasks that require precise material removal and shaping. Its effectiveness in grinding and polishing operations ensures that metal components meet exact specifications and quality standards.

Glass and Stone Polishing

Brown aluminum oxide is also used in the glass and stone industries for polishing applications. It helps in achieving a smooth and reflective surface, enhancing the aesthetic appeal of glass products and stone surfaces.

Surface Preparation

In addition to blasting, brown aluminum oxide is used for surface preparation in various industries. It ensures that surfaces are clean and free from contaminants before further processing. This is crucial in industries such as automotive and aerospace, where precision and cleanliness are paramount.

Adhesion Enhancement

Proper surface preparation using brown aluminum oxide enhances the adhesion of paints, coatings, and adhesives. This is particularly important in sectors where the integrity of bonded surfaces is critical, such as construction and manufacturing.

Precision Applications

In industries that demand high precision, such as electronics and aerospace, brown aluminum oxide is used to prepare surfaces with exacting standards. Its consistent performance ensures that components meet stringent quality requirements.

Refractory Applications

Brown aluminum oxide is also used in the production of refractory materials. Its ability to withstand high temperatures makes it an ideal ingredient in products that need to resist thermal shock and chemical attack. These products are essential in industries such as steel manufacturing and cement production.

High-Temperature Resistance

In refractory applications, the high melting point of brown aluminum oxide is a key advantage. It ensures that refractory products maintain their structural integrity under extreme heat, which is essential for processes like steelmaking and glass production.

Chemical and Thermal Stability

The chemical and thermal stability of brown aluminum oxide makes it suitable for use in harsh environments where exposure to aggressive chemicals and high temperatures is common. This stability extends the lifespan of refractory products and enhances their performance.

Anti-Slip Surfaces

Due to its abrasive nature, brown aluminum oxide is used to create anti-slip surfaces. It is often added to paints and coatings to enhance traction on floors, stairs, and other surfaces. This application is particularly important in industrial and commercial settings where safety is a priority.

Safety Enhancements

By incorporating brown aluminum oxide into coatings, manufacturers can significantly improve the safety of walking surfaces. This is crucial in environments where slip hazards are a concern, such as factories, warehouses, and public spaces.

Customizable Traction

The level of traction provided by anti-slip surfaces can be customized by adjusting the concentration and particle size of brown aluminum oxide in the coatings. This flexibility allows for tailored solutions to meet specific safety requirements.

How to Choose Brown Aluminum Oxide

When selecting brown aluminum oxide for your specific application, consider the following factors:

- Grit Size: The size of the abrasive particles can affect the finish and speed of the process. Finer grits are used for polishing, while coarser grits are better for heavy-duty blasting.

Application-Specific Grit Selection

Choosing the right grit size is crucial for achieving the desired results. For delicate polishing tasks, a finer grit provides a smooth finish, while a coarser grit is ideal for aggressive material removal. Understanding the specific requirements of your application will guide you in selecting the most appropriate grit size.

- Purity: Higher purity levels of brown aluminum oxide provide better performance. Ensure that the product you choose meets the required specifications for your application.

Assessing Purity Levels

The purity of brown aluminum oxide can significantly impact its performance. Higher purity levels result in more consistent and effective abrasive action. When selecting a product, consider the purity required for your application to ensure optimal results and efficiency.

- Recycling Capabilities: Consider the recyclability of the abrasive. Choosing a product that can be reused multiple times can lead to cost savings and environmental benefits.

Evaluating Recycling Options

The ability to recycle brown aluminum oxide not only reduces environmental impact but also lowers operational costs. When choosing an abrasive, assess the recycling capabilities offered by the supplier, as this can enhance the sustainability and cost-effectiveness of your operations.

Conclusion

Brown aluminum oxide is a versatile and durable abrasive material that offers numerous benefits across various industries. From abrasive blasting to surface preparation, its uses are extensive and varied. By understanding its properties and applications, you can make informed decisions about incorporating brown aluminum oxide into your processes. Whether you are in manufacturing, construction, or any other industry, this material can enhance efficiency and improve outcomes.