Alumina, also known as aluminum oxide, is a material with a wide range of applications due to its unique properties. From industrial manufacturing to high-tech electronics and biomedical implants, alumina‘s versatility is largely due to its distinct characteristics. One of the critical properties that influence its use in various fields is its density, a factor that significantly affects performance, durability, and efficiency. In this article, we will explore what alumina is, why its density is important, and how it affects the material’s performance in different applications.

Alumina is a compound composed of aluminum and oxygen, with the chemical formula Al₂O₃. It is a white or nearly colorless crystalline substance found in various minerals, most notably bauxite, which is the primary source of aluminum. As an abundant and naturally occurring compound, alumina is extracted from bauxite through the Bayer process and is a critical intermediate step in the production of aluminum metal.

Alumina has several properties that make it ideal for industrial use:

- Hardness: Alumina ranks high on the Mohs hardness scale, making it incredibly suitable for abrasive applications where cutting, grinding, or polishing is required.

- Thermal Stability: Withstanding temperatures exceeding 2000°C, alumina’s thermal stability is essential in applications where high thermal resistance is crucial, such as in furnaces and kilns.

- Electrical Insulation: It is an excellent electrical insulator, enabling its use in electrical and electronic applications where prevention of electrical conduction is necessary.

- Corrosion Resistance: Alumina’s resistance to chemical attacks makes it durable in harsh environments, suitable for use in chemical processing equipment and protective coatings.

These properties not only enhance its applicability but also ensure that alumina remains a material of choice across various industries, from aerospace to electronics. For more information on alumina’s diverse applications, visit our alumina versatile uses guide.

The Importance of Density in Alumina

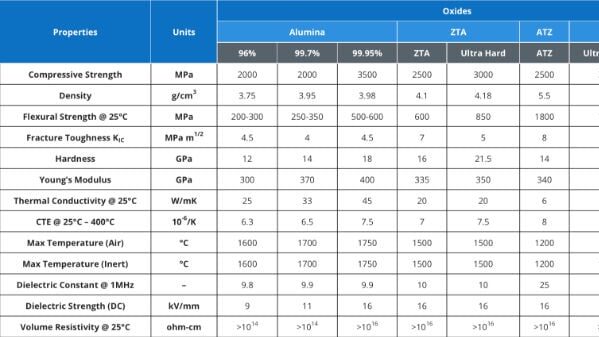

The density of alumina is a crucial factor that affects its performance in various applications. The density of a material is its mass per unit volume, typically expressed in grams per cubic centimeter (g/cm³). For alumina, the typical density is approximately 3.95 to 4.10 g/cm³, a range that reflects its compact crystalline structure.

Key Impacts of Density on Alumina Properties:

- Strength and Durability: The density of alumina directly impacts its mechanical strength and durability. Higher-density materials typically exhibit greater structural integrity, making them ideal for applications that require robust and long-lasting components.

- Thermal Conductivity: Density influences thermal conductivity. Denser materials usually have superior thermal conductivity, which is essential in applications that require efficient heat dissipation or management.

- Wear Resistance: Higher density often correlates with increased wear resistance, a critical factor in applications involving continuous friction, abrasion, or mechanical stress.

- Weight Considerations: In industries like aerospace and automotive, where minimizing weight without sacrificing strength is crucial, understanding alumina’s density aids in designing components that are both lightweight and structurally sound.

Measuring the Density of Alumina

The density of alumina can be measured using various methods. These measurement techniques are crucial for ensuring that the material’s properties meet the specific requirements of its intended application.

- Displacement Method: This method involves submerging a sample of alumina in a fluid and measuring the volume of fluid displaced. The density is then calculated using the formula: Density=Volume of Displaced FluidMass of the Sample This traditional method is widely used due to its simplicity and effectiveness, particularly for solid alumina samples.

- Helium Pycnometry: Helium pycnometry measures the volume of a gas displaced by the sample. It’s a precise method often used for powdered materials, offering accuracy by considering even the smallest pores within the sample, which might not be detected by other methods.

- X-Ray Diffraction: This technique involves analyzing the crystal structure of alumina to determine its density. It’s particularly useful for high-purity alumina, where even slight variations in crystal lattice can significantly impact density measurements, ensuring precision in applications requiring exact specifications.

Applications of Alumina Based on Density

Different applications of alumina require specific densities for optimal performance. The choice of density is often dictated by the functional requirements of the application.

High-Density Alumina for Refractories:

In the production of refractories, high-density alumina is preferred for its ability to withstand extreme temperatures and resist thermal shock. Refractories are used in furnaces, kilns, and reactors, where they provide structural support and insulation in high-temperature environments, ensuring safety and efficiency.

Abrasive Applications:

Alumina‘s hardness and density make it an excellent choice for abrasive applications. High-density alumina is used in grinding wheels, sandpaper, and cutting tools, where its wear resistance and toughness allow for effective material removal and finishing processes in manufacturing and construction.

Electronics and Biomedical Applications:

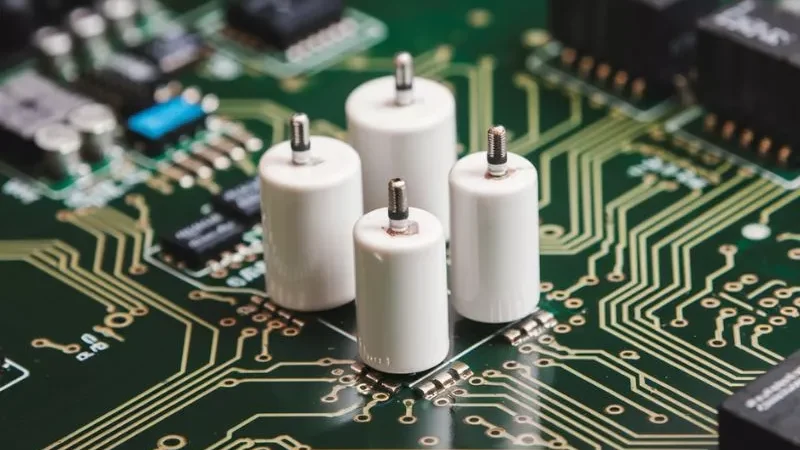

For electronic applications, alumina’s electrical insulating properties are essential. The material’s density ensures that it provides adequate insulation while maintaining structural integrity in components like substrates and insulators, crucial for preventing electrical failures and enhancing device reliability.

In the biomedical field, alumina is used in implants such as hip replacements. The density of the material ensures that implants are both strong and lightweight, reducing the stress on the body and enhancing patient comfort and mobility, while also ensuring biocompatibility and longevity.

Factors Affecting the Density of Alumina

Several factors can influence the density of alumina materials, affecting their suitability for different applications:

- Purity: The purity of alumina can significantly affect its density. Impurities can create voids or alter the crystal structure, leading to changes in density. High-purity alumina is critical in applications where consistent material properties are essential, such as in electronics and high-precision engineering.

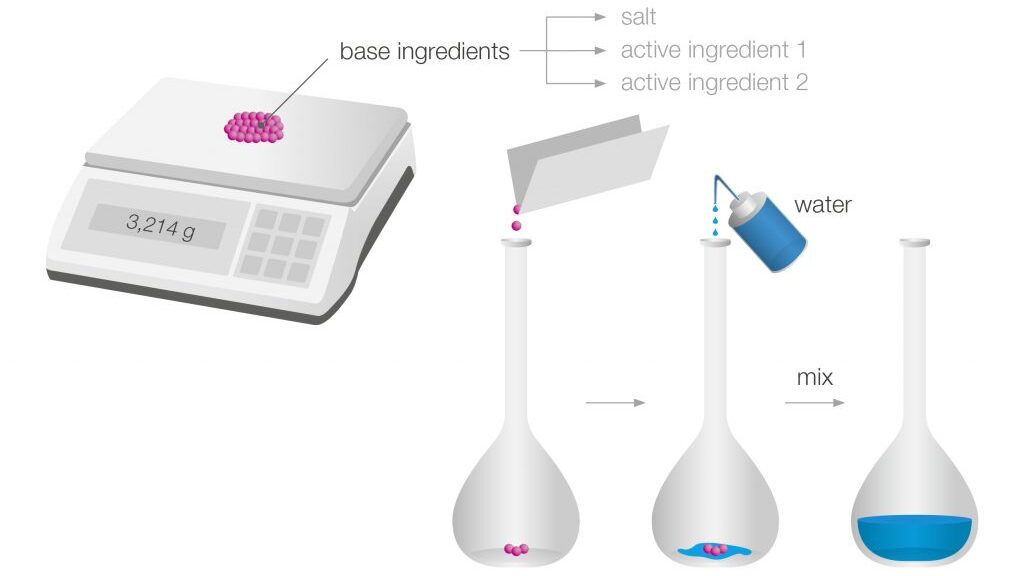

- Sintering: Sintering is a process used to compact and form solid materials. The sintering temperature can affect the density of alumina. Higher temperatures generally result in denser materials due to better particle bonding, enhancing strength and reducing porosity.

- Additives: Additives can be introduced to modify the properties of alumina. These additives can alter the density by affecting the material’s microstructure. Tailoring alumina with additives allows customization of its properties for specific applications, such as enhancing toughness or reducing weight.

FAQ: Frequently Asked Questions about the Density of Alumina

Q1: What is the typical density of alumina?

A1: The typical density of alumina is between 3.95 to 4.10 g/cm³, reflecting its compact crystalline structure.

Q2: How does the density of alumina affect its performance?

A2: Density affects alumina’s strength, durability, thermal conductivity, wear resistance, and weight, making it crucial in applications like refractories, abrasives, and electronic components.

Q3: Can the density of alumina be modified?

A3: Yes, the density of alumina can be modified through factors like sintering temperature, purity, and the addition of additives, allowing for customization of alumina’s properties.

Q4: What industries benefit from alumina’s density?

A4: Industries like aerospace, automotive, electronics, and biomedicine benefit from alumina’s density, especially in applications requiring strength, durability, and precise insulation.

Conclusion

In summary, the density of alumina is more than just a number—it’s a fundamental characteristic that defines how this versatile material can be used to its fullest potential. Recognizing its importance allows for innovation and efficiency across industries, highlighting alumina’s indispensable role in modern technology and manufacturing. By considering factors like purity, sintering temperature, and additives, manufacturers can tailor the density of alumina to meet specific needs, ensuring optimal performance and durability.