Alumina, often referred to as aluminum oxide, is a foundational material in the production of aluminum metal. The extraction of alumina from bauxite ore is a critical phase in the aluminum manufacturing process. Over the decades, numerous innovative techniques have been developed to enhance the efficiency and sustainability of alumina extraction. This article delves into these cutting-edge methods and examines their transformative impact on the industry.

To appreciate the innovative techniques in alumina extraction, it is crucial first to grasp the conventional methods. The Bayer process remains the most prevalent method globally. This procedure involves dissolving bauxite ore in sodium hydroxide, which separates alumina from impurities. The resulting solution undergoes filtration and cooling, leading to the crystallization of alumina.

The Bayer Process: An Overview

The Bayer process was developed in the late 19th century and has been the cornerstone of alumina extraction. Bauxite, rich in aluminum-bearing minerals, is treated with a concentrated sodium hydroxide solution at elevated temperatures. This results in the formation of a soluble sodium aluminate solution while insoluble impurities settle as red mud. The alumina is then precipitated from the solution upon cooling.

Limitations of the Bayer Process

Despite its widespread use, the Bayer process has significant drawbacks. It is notably energy-intensive, requiring high temperatures and pressures, contributing to substantial energy costs. Furthermore, the process generates a large quantity of red mud, a hazardous waste product that poses environmental disposal challenges. These limitations have catalyzed research into alternative methods.

Environmental and Economic Impacts

The environmental impact of the Bayer process is profound. Red mud disposal is a major ecological concern due to its caustic nature and volume. Additionally, the energy demands contribute to high operational costs and carbon emissions. These factors have driven the industry to seek more sustainable and cost-effective alternatives.

Hydrothermal Processing

Hydrothermal processing has emerged as a promising technique for alumina extraction. This method involves treating bauxite ore with high-pressure steam, which alters the ore’s structure and facilitates alumina release.

Mechanism of Hydrothermal Processing

Hydrothermal processing operates under conditions of elevated pressure and temperature, using steam to penetrate the bauxite ore matrix. This process alters the mineralogical structure, promoting the liberation of alumina. The steam acts as both a physical and chemical agent, breaking down the ore more efficiently than traditional methods.

Benefits of Hydrothermal Processing

- Reduced Energy Consumption: Hydrothermal processing is less energy-intensive compared to the Bayer process. The use of high-pressure steam enables effective ore breakdown without the necessity for extreme temperatures, reducing overall energy requirements.

- Lower Waste Generation: A significant advantage of hydrothermal processing is the reduction in red mud production. By minimizing the generation of this byproduct, the method reduces the environmental footprint of alumina extraction.

- Improved Alumina Recovery: This technique enhances alumina recovery rates, enabling the extraction of a higher percentage of alumina from the bauxite ore. This improves the overall efficiency and profitability of the extraction process.

Challenges and Future Prospects

Despite its advantages, hydrothermal processing faces challenges such as equipment costs and operational complexities. Ongoing research aims to optimize the process, making it more accessible and economically viable for large-scale adoption.

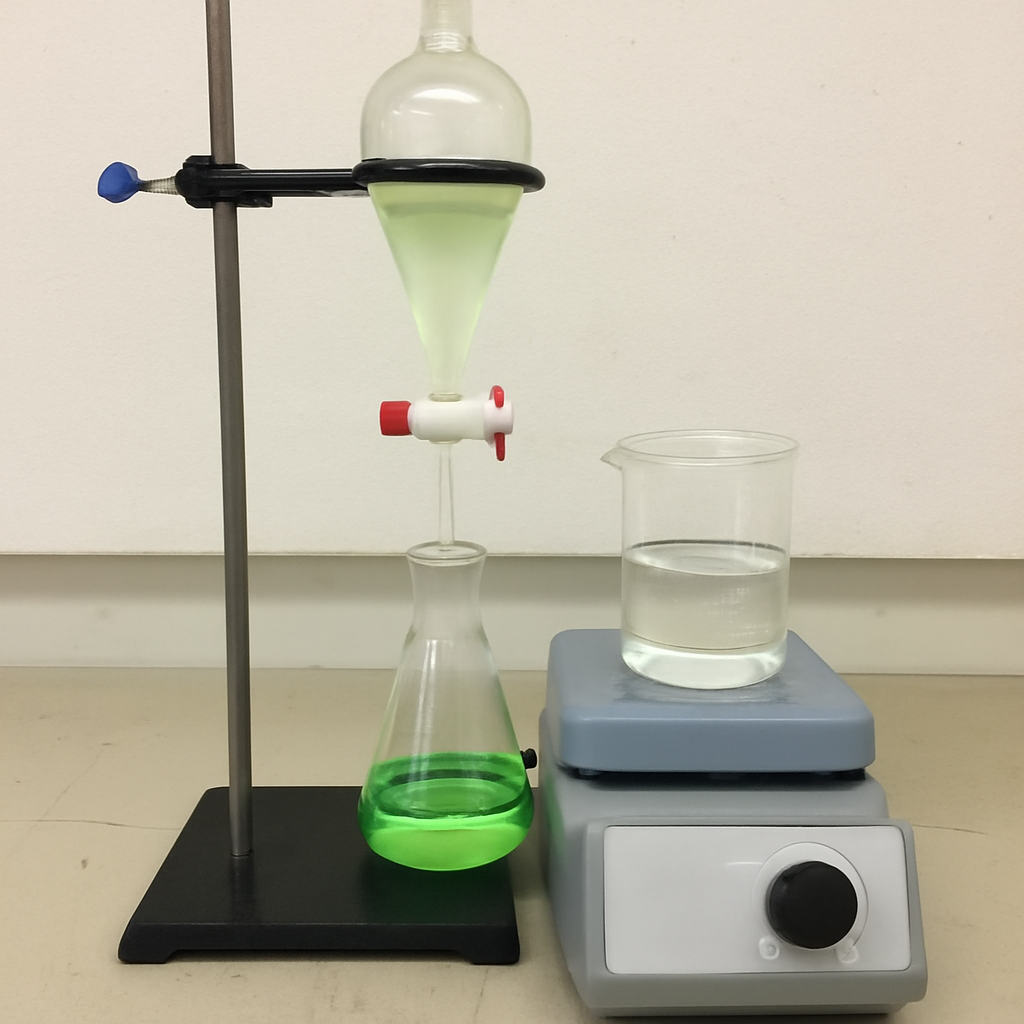

Solvent Extraction Techniques

Solvent extraction presents another innovative approach to alumina extraction. This technique employs organic solvents to selectively dissolve alumina from the bauxite ore.

The Science Behind Solvent Extraction

Solvent extraction involves using specific organic solvents to target and dissolve alumina from the bauxite matrix. The process capitalizes on the chemical affinity of the solvent for alumina, allowing for selective extraction. This method is highly adaptable, with various solvents being explored to optimize efficiency and minimize environmental impact.

Advantages of Solvent Extraction

- Selective Extraction: The precision of solvent extraction lies in its ability to selectively target alumina, minimizing the extraction of unwanted impurities. This enhances the purity of the final product, making it suitable for high-quality applications.

- Scalability: Solvent extraction can be effectively scaled up for industrial-level production. Its adaptability allows for easy integration into existing facilities, supporting large-scale operations.

- Reduced Environmental Impact: By significantly reducing waste generation and energy consumption, solvent extraction offers a more sustainable option for alumina extraction. This aligns with global efforts to minimize the environmental footprint of industrial processes.

Innovations and Developments

Ongoing research in solvent extraction focuses on discovering new solvent systems that are more environmentally benign and cost-effective. Developments in this area promise to enhance the sustainability and efficiency of the alumina extraction process.

Electrolytic Processes

Electrolytic processes are gaining traction in the realm of alumina extraction. These methods utilize electric currents to separate alumina from the bauxite ore. Among these, molten salt electrolysis stands out as a particularly promising technique.

Principles of Electrolytic Extraction

Electrolytic extraction relies on electrochemical principles to facilitate the separation of alumina. In molten salt electrolysis, alumina is dissolved in a molten salt bath, and an electric current is applied. This causes aluminum ions to migrate and deposit as pure aluminum at the cathode.

Molten Salt Electrolysis

by NOAA (https://unsplash.com/@noaa)

Molten salt electrolysis is a groundbreaking technique that involves the dissolution of alumina in a molten salt medium, followed by the application of an electric current to separate aluminum ions.

Benefits of Molten Salt Electrolysis

- High Purity Product: The electrolytic process yields high-purity alumina, suitable for a wide range of industrial applications. The purity level achieved is superior to that of traditional methods.

- Energy Efficiency: Compared to conventional extraction methods, molten salt electrolysis is markedly more energy-efficient. This reduces the overall energy consumption, making the process economically attractive.

- Reduced Carbon Emissions: By eliminating the need for carbon-based reducing agents, this method significantly reduces carbon emissions associated with alumina extraction. This aligns with global initiatives to reduce industrial carbon footprints.

Potential and Challenges

While molten salt electrolysis holds significant promise, challenges remain in terms of operational costs and the development of suitable molten salt systems. Research is ongoing to address these issues and enhance the feasibility of this technique.

The Role of Biotechnology in Alumina Extraction

Biotechnology has emerged as a promising frontier for enhancing alumina extraction processes. Researchers are investigating the use of microorganisms to improve the efficiency and sustainability of alumina extraction.

Microbial Leaching: A Biotechnological Approach

Microbial leaching, also known as bioleaching, employs bacteria to extract alumina from bauxite ore. This method leverages the natural metabolic processes of microorganisms to facilitate alumina liberation.

Advantages of Microbial Leaching

- Environmentally Friendly: Bioleaching represents a green technology that significantly minimizes the environmental impact of alumina extraction. It reduces the need for harsh chemicals and energy-intensive processes.

- Cost-Effective: The cost-effectiveness of microbial leaching lies in its reduction of expensive chemical inputs and energy consumption. This method holds the potential to lower overall production costs substantially.

- Versatility: One of the key advantages of microbial leaching is its applicability to low-grade bauxite ores. This expands the range of raw materials available for alumina extraction, enhancing resource utilization.

Current Research and Future Directions

While microbial leaching is still in the experimental stage, ongoing research aims to optimize microbial strains and leaching conditions. The integration of biotechnology in alumina extraction promises to revolutionize the industry.

Conclusion

Innovative techniques in alumina extraction are reshaping the industry, making it more efficient, sustainable, and cost-effective. From hydrothermal processing and solvent extraction to electrolytic processes and biotechnology, these methods provide promising alternatives to traditional extraction methods. As research and development progress, we can anticipate further advancements that will propel the industry towards a more sustainable future.

By adopting these innovative techniques, companies can reduce their environmental footprint, lower production costs, and enhance the overall efficiency of the alumina extraction process. Consequently, the aluminum industry will be better equipped to meet the growing global demand for this essential material, supporting sustainable growth and technological advancement.