Alumina, or aluminum oxide, is a ceramic material composed of aluminum and oxygen, with the chemical formula Al2O3. It is a white, crystalline substance, commonly found in its natural form as corundum. The compound is widely used in various applications due to its exceptional hardness, high melting and boiling points, and excellent thermal conductivity.

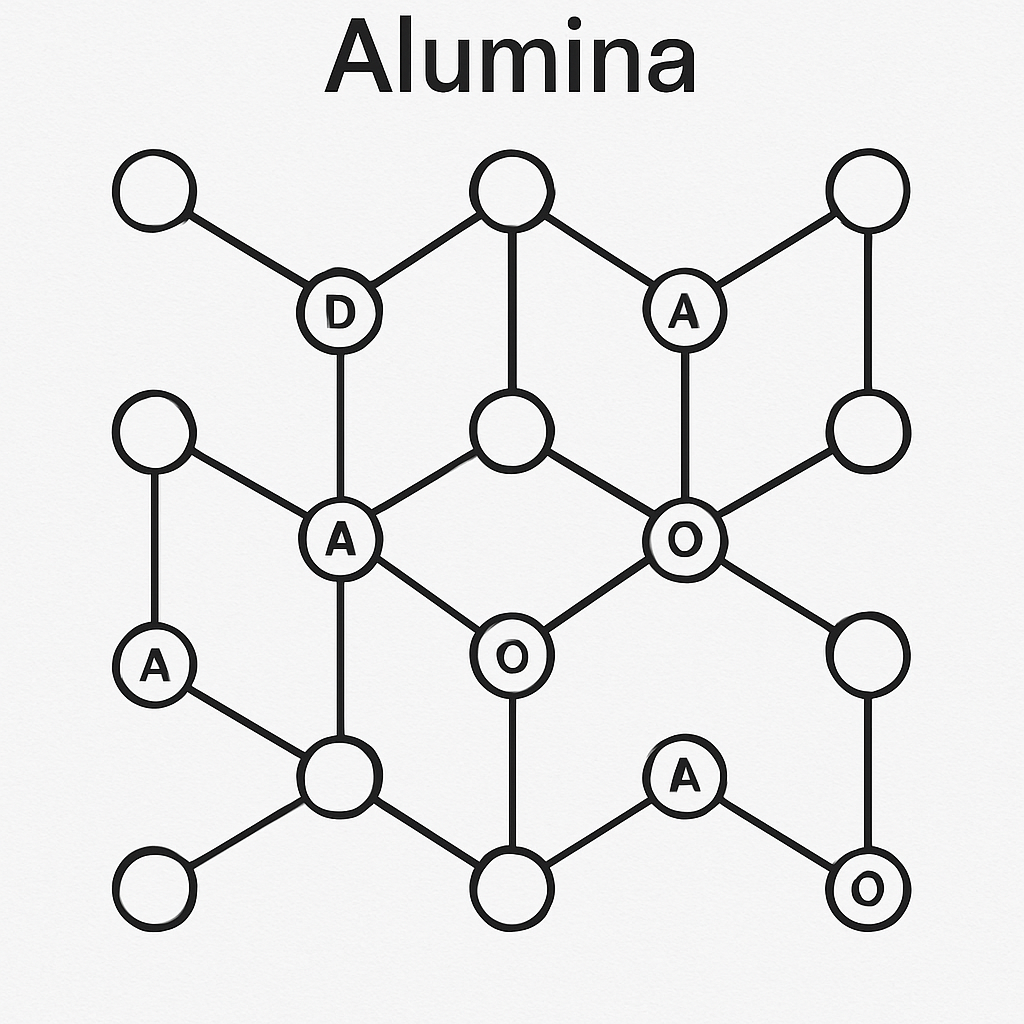

Alumina structure diagramComposition and Structure

Alumina is primarily composed of aluminum and oxygen atoms arranged in a crystalline lattice. This structure gives alumina its unique properties, such as high hardness and stability. The arrangement of atoms is crucial for its ability to maintain structural integrity under extreme conditions.

Natural Occurrence and Extraction

Naturally occurring alumina is found in the mineral corundum, which also forms the basis for precious gemstones like sapphires and rubies. The extraction process involves mining bauxite ore, which is then refined to produce pure alumina. This extraction and refinement process is essential for its widespread industrial applications.

Industrial Significance

Alumina’s industrial significance cannot be overstated. It is used as a raw material in the production of aluminum metal, serving as a vital component in the aluminum industry. Additionally, due to its hardness and thermal properties, alumina finds applications in manufacturing, electronics, and chemical industries, among others.

The Importance of Alumina Density

The density of a material affects its performance and suitability for specific applications. For alumina, density is a key factor that influences its mechanical and thermal properties. Understanding alumina’s density helps in selecting the right material for engineering applications, ensuring optimal performance and longevity.

Impact on Mechanical Properties

The density of alumina directly affects its mechanical strength and durability. A higher density typically correlates with increased strength and resistance to deformation, making alumina ideal for load-bearing and high-stress applications. Engineers rely on this property to design components that can withstand significant forces without failure.

Influence on Thermal Performance

Density also plays a critical role in determining alumina’s thermal performance. A denser material often has better thermal conductivity, allowing it to efficiently dissipate heat. This characteristic is particularly beneficial in high-temperature environments where thermal management is crucial to prevent component failure.

Role in Material Selection

When selecting materials for specific applications, density is a fundamental consideration. For industries such as aerospace or electronics, where weight and space constraints are significant, understanding the density of alumina helps in making informed decisions. This ensures that components not only perform optimally but also meet design and regulatory requirements.

Alumina’s Physical Properties

Alumina exhibits a range of remarkable physical properties that make it suitable for a variety of uses. Here are some of the key properties:

Hardness and Strength

Alumina is known for its high hardness, making it resistant to wear and abrasion. On the Mohs hardness scale, aluminum oxide registers a value of around 9, just below diamond. This hardness is crucial in applications such as cutting tools, abrasives, and wear-resistant components.

Applications in Abrasives

The hardness of alumina makes it an excellent material for abrasive applications. It is used in grinding wheels, sandpapers, and cutting discs, providing efficient material removal and surface finishing. The durability of alumina abrasives ensures long-lasting performance, reducing the need for frequent replacements.

Wear Resistance in Industrial Components

In industrial settings, alumina’s wear resistance is invaluable. Components exposed to high friction environments, such as conveyor belts and pump impellers, benefit from alumina’s ability to withstand abrasion. This property extends the lifespan of machinery, leading to reduced maintenance costs and downtime.

Role in Cutting Tools

Alumina’s hardness is also leveraged in the production of cutting tools for machining metals and other materials. These tools maintain sharpness and precision over extended periods, improving manufacturing efficiency. The reliability of alumina-based cutting tools makes them essential in various industrial applications.

Yield and Tensile Strength

The yield strength of alumina is the stress at which it begins to deform plastically. Alumina’s yield strength is relatively high, which means it can withstand significant stress before deforming. Its tensile strength is also noteworthy, making it suitable for load-bearing applications.

Structural Integrity in Load-Bearing Applications

Alumina’s yield and tensile strengths are critical for structural applications where load-bearing capacity is essential. In construction and engineering projects, materials with high strength are required to support weight and withstand external forces. Alumina’s properties ensure that structures remain stable and secure.

Use in Pressure Vessels and Pipelines

In industries like oil and gas, alumina is used in the construction of pressure vessels and pipelines. These structures must endure high internal pressures without failure. Alumina’s strength properties make it a reliable choice, providing safety and efficiency in these demanding environments.

Importance in Safety-Critical Components

For safety-critical components, such as those in the aerospace and automotive industries, alumina’s strength is indispensable. The ability to withstand stress without deformation ensures that these components function reliably, minimizing the risk of accidents and enhancing overall safety.

Density of Alumina

The density of alumina is approximately 3.95 to 4.1 grams per cubic centimeter (g/cm³). This density contributes to its robustness and ability to withstand mechanical stress. The high density also influences its thermal conductivity, making it effective in heat-resistant applications.

Correlation with Mechanical Performance

The density of alumina is closely linked to its mechanical performance. A higher density provides greater resistance to impact and fracture, essential for applications involving dynamic loads. This property is particularly beneficial in industries where mechanical stability is paramount.

Enhancement of Thermal Conductivity

Density enhances alumina’s thermal conductivity, allowing it to efficiently transfer heat. This makes it ideal for applications requiring rapid heat dissipation, such as heat sinks and thermal barrier coatings. The ability to manage heat effectively is crucial in preventing overheating and maintaining operational efficiency.

Role in Weight-Sensitive Applications

In weight-sensitive applications, such as aerospace or automotive engineering, the density of alumina must be carefully considered. While providing strength and thermal properties, its weight must not compromise the overall design. Engineers balance these factors to optimize performance and efficiency.

Thermal Properties

Alumina’s thermal conductivity is another standout feature. It efficiently conducts heat, making it ideal for thermal management applications. Its melting temperature is around 2072°C (3762°F), and its boiling point is approximately 2977°C (5391°F), which allows it to maintain stability in high-temperature environments.

Thermal Management in Electronics

Alumina’s thermal properties are crucial in electronics, where heat dissipation is vital. It is used in substrates and heat sinks to manage heat generated by electronic components. This prevents overheating, ensuring reliable performance and longevity of electronic devices.

Applications in High-Temperature Environments

In industries such as metallurgy and glass manufacturing, alumina’s ability to withstand high temperatures is invaluable. Its stability at elevated temperatures makes it suitable for furnace linings and crucibles. These applications require materials that maintain integrity in extreme heat, a role alumina fulfills effectively.

Importance in Thermal Barrier Coatings

Alumina is also used in thermal barrier coatings, protecting components from thermal shock and heat damage. These coatings are applied to turbine blades and engine parts, enhancing their durability and efficiency. The thermal properties of alumina ensure these coatings perform under demanding conditions.

Applications of Alumina

The properties of alumina make it suitable for a wide range of applications across various industries:

Industrial Applications

- Abrasives: Due to its hardness, alumina is used in abrasive materials for grinding, cutting, and polishing.

- Refractories: Its high melting point makes it suitable for use in furnaces and kilns.

- Ceramics: Alumina is a key component in ceramic materials, offering strength and wear resistance.

Role in Grinding and Polishing

In grinding and polishing applications, alumina’s hardness ensures efficient material removal and surface finishing. It is used in a variety of abrasive products, from industrial grinding wheels to consumer sandpapers. The durability of alumina abrasives leads to longer-lasting tools and better surface quality.

Significance in Refractory Materials

Alumina’s high melting point makes it an ideal choice for refractory materials used in high-temperature environments. It is used in the linings of furnaces, kilns, and incinerators, providing thermal insulation and structural integrity. This application is critical for industries that operate under extreme thermal conditions.

Contribution to Ceramic Engineering

In ceramic engineering, alumina is valued for its strength and wear resistance. It is used in the production of technical ceramics, including tiles, insulators, and wear-resistant components. Alumina ceramics are essential in industries ranging from aerospace to electronics, where performance and reliability are paramount.

Electrical Applications

Alumina’s electrical insulating properties make it valuable in electrical and electronic components, such as insulators and substrates for microelectronic devices.

Use in Electrical Insulation

Alumina is widely used as an electrical insulator due to its excellent dielectric properties. It is found in insulators for high-voltage applications, ensuring safe and efficient power transmission. Alumina’s insulation capabilities prevent electrical failures and enhance system reliability.

Substrates for Microelectronics

In microelectronics, alumina serves as a substrate material for integrated circuits and semiconductor devices. Its thermal and electrical properties make it ideal for supporting complex electronic components. Alumina substrates contribute to the miniaturization and performance of modern electronic devices.

Role in High-Frequency Applications

Alumina’s low dielectric loss makes it suitable for high-frequency applications, such as microwave and RF components. It is used in dielectric resonators and filters, ensuring signal integrity and performance. This application is crucial in telecommunications and radar systems.

Mechanical and Structural Applications

Its strength and durability allow alumina to be used in mechanical seals, bearings, and cutting tools. The material’s ability to withstand mechanical stress and high temperatures makes it ideal for these applications.

Importance in Mechanical Seals

Alumina is used in mechanical seals for pumps and compressors, providing resistance to wear and chemical attack. These seals ensure leak-free operation and extend the lifespan of equipment. The reliability of alumina seals is critical in industries such as chemical processing and oil and gas.

Use in Bearings and Wear Components

In bearings and wear components, alumina’s strength and wear resistance are indispensable. It is used in applications where low friction and durability are essential, such as automotive and industrial machinery. Alumina bearings reduce maintenance needs and improve operational efficiency.

Applications in Cutting Tools

Alumina is a key material in the manufacture of cutting tools for machining metals, ceramics, and composites. Its hardness and thermal stability allow tools to maintain sharpness and precision, enhancing productivity. The use of alumina in cutting tools is widespread in manufacturing industries.

Understanding Alumina’s Modulus of Elasticity

The modulus of elasticity, also known as the elastic modulus, measures a material’s ability to deform elastically when a force is applied. For alumina, the modulus of elasticity is relatively high, indicating that it is rigid and resists elastic deformation. This property is crucial in applications requiring structural integrity and precision.

Elasticity in Structural Applications

Alumina’s high modulus of elasticity ensures that it maintains shape and structure under load, making it ideal for structural applications. In construction and engineering, materials that resist elastic deformation are necessary to ensure stability and safety. Alumina meets these requirements, providing reliable performance.

Precision in Engineering Components

In engineering components, such as gears and precision instruments, alumina’s elasticity is essential. It allows these components to maintain their shape and function under stress, ensuring accuracy and reliability. The precision offered by alumina is vital in industries where performance cannot be compromised.

Importance in Load-Bearing Scenarios

For load-bearing scenarios, alumina’s modulus of elasticity provides the rigidity needed to support weight and resist deformation. This property is critical in applications like bridge construction and heavy machinery, where structural integrity is paramount. Alumina’s performance in these roles enhances safety and efficiency.

Thermal Conductivity of Alumina

Alumina’s thermal conductivity is a key factor in its effectiveness as a thermal insulator. Its ability to conduct heat efficiently allows it to dissipate heat in high-temperature applications, protecting sensitive components from thermal damage.

Heat Dissipation in Electronics

In electronics, alumina’s thermal conductivity is leveraged to dissipate heat from components, preventing overheating. It is used in heat sinks and thermal management systems, ensuring devices operate within safe temperature ranges. This application is critical for maintaining the performance and lifespan of electronic equipment.

Role in High-Temperature Insulation

Alumina is used as an insulating material in high-temperature applications, such as furnace linings and thermal barriers. Its thermal conductivity allows it to manage heat transfer, protecting equipment from thermal stress. This property is essential for maintaining operational efficiency and safety.

Applications in Energy Systems

In energy systems, such as power plants and solar panels, alumina’s thermal conductivity is utilized to enhance efficiency. It facilitates heat transfer processes, improving energy conversion and output. Alumina’s role in these systems contributes to sustainable and efficient energy production.

Conclusion

Alumina, or aluminum oxide, is a versatile material with a range of properties that make it indispensable in various industries. Its density, hardness, thermal conductivity, and strength are just a few of the characteristics that contribute to its widespread use. Understanding these properties allows engineers and manufacturers to select the right material for their specific needs, ensuring optimal performance and durability.

Significance in Industrial Progress

Whether used in abrasives, refractories, or electronic components, alumina continues to be a valuable material, driving innovation and efficiency in multiple fields. Its unique properties make it a material of choice for applications that demand high performance and reliability.

Advancements in Technology and Manufacturing

By understanding the density and other related properties of alumina, industries can continue to leverage its benefits, leading to advancements in technology and manufacturing processes worldwide. Alumina’s role in these advancements highlights its importance in achieving technological progress and industrial growth.

Future Prospects and Developments

As industries evolve and new challenges arise, the demand for materials like alumina is expected to grow. Ongoing research and development efforts aim to enhance its properties and discover new applications, ensuring that alumina remains at the forefront of material science and engineering innovation.

[…] Pure aluminum conducts electricity better than aluminum alloys. The presence of other elements can impede the free movement of electrons. In industrial settings, ensuring high purity levels is essential to maximize conductivity. This is why applications demanding high efficiency, such as in the aerospace sector, often use high-purity aluminum. […]