1. Introduction

In the industrial abrasives industry, White Corundum (White Fused Alumina) and Brown Corundum (Brown Fused Alumina) are two of the most widely used materials. They are commonly applied in grinding, polishing, sandblasting, cutting, surface treatment, and refractory materials.

Although both are aluminum oxide abrasives, they differ significantly in purity, hardness, toughness, application scenarios, and cost.

This article provides a comprehensive comparison to help you determine which corundum to choose for your application.

2. What Is White Corundum?

2.1 Definition & Composition

White Corundum is produced by melting and fusing high-purity aluminum oxide (Al₂O₃ ≥ 99%) in an electric arc furnace, then cooling and crushing. It contains almost no iron or other impurities, making it ideal for precision applications.

2.2 Key Properties

- Extremely high hardness (Mohs 9)

- Self-sharpening: forms new cutting edges during grinding

- Low impurities and iron content: avoids material contamination

- High chemical stability

- Uniform particle size and white appearance

2.3 Common Applications

- Precision grinding (precision parts, ceramics, bearings)

- Polishing (glass, gemstones, electronic components)

- Stainless steel and aluminum surface treatment

- Surface preparation for sandblasting

- High-performance refractory materials

3. What Is Brown Corundum?

3.1 Definition & Composition

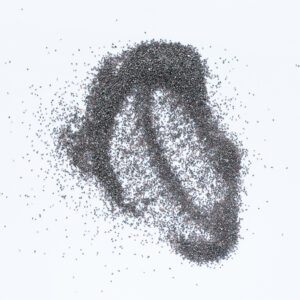

Brown Corundum is produced by fusing bauxite, iron oxide, and carbon, with Al₂O₃ content typically around 95–97%. Impurities such as Fe₂O₃ and TiO₂ give it a brown to dark brown color.

3.2 Key Properties

- High toughness and impact resistance

- Higher bulk density

- Durable and resistant to breakage during grinding

- Lower cost compared to White Corundum

- Suitable for large-scale industrial sandblasting and rough grinding

3.3 Common Applications

- Industrial sandblasting (rust, old paint removal)

- Heavy-duty grinding (steel processing, foundry)

- Anti-slip flooring

- Refractory materials (castables, refractory bricks)

4. White Corundum vs Brown Corundum: Key Differences

| Property | White Corundum | Brown Corundum |

|---|---|---|

| Al₂O₃ Content | ≥ 99% | 95–97% |

| Iron Content | Very Low | Higher |

| Hardness | High | Medium-High |

| Toughness | Low | High |

| Price | Higher | Lower |

| Main Uses | Precision Grinding, Polishing | Sandblasting, Rough Grinding, Refractory |

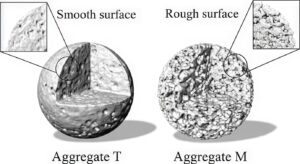

4.1 Color Difference

- White Corundum: white

- Brown Corundum: dark brown to black-brown

Color differences are caused by different impurities.

4.2 Grinding Performance

- White Corundum: sharp and self-sharpening, cleaner for precision work

- Brown Corundum: stronger impact, suitable for rough grinding and heavy-duty operations

4.3 Reusability

- White Corundum: high hardness but brittle, limited reuse

- Brown Corundum: tougher, more reusable

[IMAGE PLACEHOLDER: Hardness & Toughness Comparison]

5. Which One Should You Use?

5.1 Precision Grinding & Polishing → White Corundum

- Precision parts, ceramics, glass

- Stainless steel and high-purity materials

- High-precision polishing

5.2 Heavy-Duty Sandblasting → Brown Corundum

- Rust and old paint removal

- Carbon steel, castings

- Large-scale industrial sandblasting

5.3 Cost Considerations

White Corundum is more expensive, while Brown Corundum is cost-effective for bulk industrial use.

6. Industry Use Cases

| Industry | Corundum Type | Reason |

|---|---|---|

| Aerospace Component Grinding | White Corundum | High precision, low contamination |

| Glass Surface Polishing | White Corundum | Precision polishing |

| Large Oil Tank Sandblasting | Brown Corundum | High impact, cost-effective |

| Foundry Rough Grinding | Brown Corundum | Durable, economical |

7. FAQ

Q1: Can White Corundum and Brown Corundum be used interchangeably?

A1: Not recommended. White Corundum is for precision work, Brown Corundum for heavy-duty applications.

Q2: How to determine White Corundum grit size?

A2: Choose according to FEPA/ANSI standards; smaller grit size yields finer grinding.

Q3: Which corundum is more eco-friendly or reusable?

A3: Brown Corundum is tougher and can be reused more times, making it cost-effective and environmentally friendly.

Q4: Which corundum should be used for stainless steel polishing?

A4: White Corundum to avoid iron contamination.

8. Conclusion

The choice between White Corundum and Brown Corundum depends on your processing requirements, material type, and budget:

- White Corundum: high purity, high hardness, for precision applications

- Brown Corundum: high toughness, cost-effective, for heavy-duty grinding and sandblasting

Understanding these differences ensures your industrial processing is more efficient, cost-effective, and precise.

9. Suggested Images

- White vs Brown Corundum Particle Comparison

- White Corundum Microstructure

- Brown Corundum Sandblasting Site

- Hardness & Toughness Comparison

- Industry Application Diagram

- Summary Comparison Visual