White fused alumina is a remarkable material with diverse applications. It is a high-purity synthetic abrasive. This material is known for its hardness and toughness.

White fused alumina is produced by fusing alumina in an electric arc furnace. The process occurs at temperatures above 2000°C. This results in a material with a high melting point.

Also known as white corundum, it has a crystalline structure. This structure contributes to its exceptional properties. It is highly resistant to chemical attack and thermal shock.

White fused alumina is used in many industries. It is essential in abrasive applications like grinding and polishing. Its versatility extends to refractory materials.

The material is available in various grit sizes. This makes it suitable for different applications. It is used in aerospace, automotive, and electronics industries.

White fused alumina is environmentally friendly. It can be recycled, adding to its appeal. Its high purity ensures minimal contamination in sensitive applications.

In this article, we will explore its benefits and applications. We will delve into its properties and industrial significance. Join us as we uncover the potential of white fused alumina.

What is White Fused Alumina?

White fused alumina is a synthetic material created through a specialized process. This process involves fusing calcined alumina under extreme heat. The result is a product with outstanding hardness and durability.

The material is often referred to as white corundum. This is because of its crystalline nature. It exhibits properties akin to natural corundum.

White fused alumina is a form of aluminum oxide. It belongs to the group of abrasives known for their toughness. Its high purity sets it apart from other abrasives.

Several features highlight its unique nature:

- High purity and minimal impurities

- Exceptional hardness and toughness

- Resistant to thermal shock and chemicals

- Available in a range of grit sizes

The electric arc furnace plays a crucial role in its production. At temperatures exceeding 2000°C, alumina is melted and cooled to form the material. This fusion gives it superior qualities.

Its applications are vast due to these properties. It is used in industries that demand precision and reliability. This includes sectors like aerospace and electronics, where quality cannot be compromised.

In summary, white fused alumina stands out for its versatility and performance. It not only meets but often exceeds industry standards. Its properties make it a preferred choice for various demanding applications.

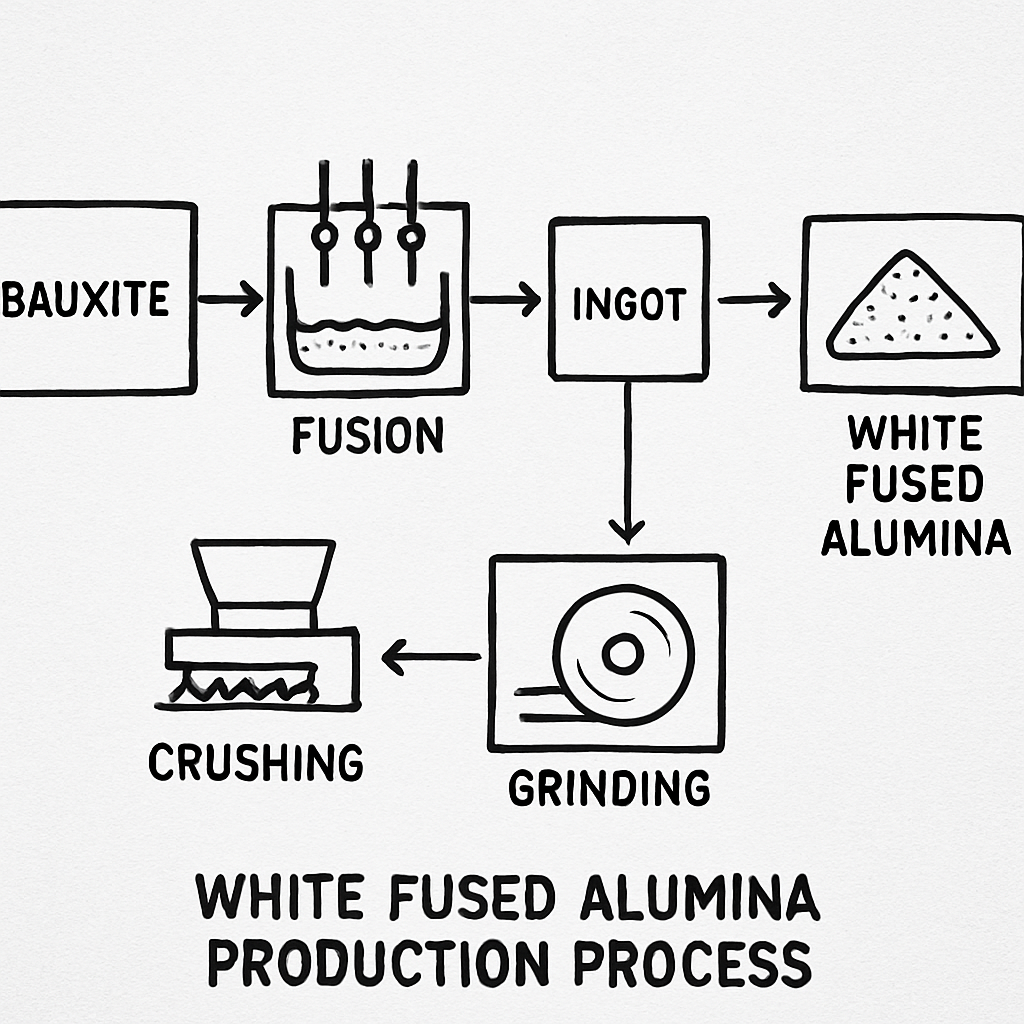

Production Process of White Fused Alumina

Producing white fused alumina involves several precise steps. First, high-purity calcined alumina is the primary raw material. This raw material must contain minimal impurities.

The process begins with the electric arc furnace. Here, calcined alumina is subjected to intense heat, often above 2000°C. This extreme temperature is necessary for fusing the alumina effectively.

During fusion, aluminum oxide is melted. As it cools, it forms solid, crystalline masses. The result is a hard and durable white corundum.

The production involves key stages:

- Selection of high-purity calcined alumina

- Melting in an electric arc furnace

- Controlled cooling to form crystals

- Crushing and sizing into specific grits

Once the fusion process is complete, the material undergoes further processing. It is crushed and sorted into various grit sizes. These sizes are tailored to meet specific industrial needs.

Quality control is essential throughout production. Each batch of white alumina undergoes rigorous testing. This ensures it meets the required standards for use.

Overall, the production process of white fused alumina is complex. Yet, it is this complexity that results in a product of exceptional quality and reliability. These attributes make it a staple in many high-performance industries.

Key Properties of White Fused Alumina

White fused alumina is revered for its unique properties. These attributes arise from its high-purity and meticulous production process. Its exceptional hardness stands out among abrasives.

This material boasts remarkable toughness. Combined with hardness, it can withstand rigorous conditions. It performs well even when exposed to extreme abrasion.

Another key property is its high melting point. This makes it suitable for high-temperature environments. Its resistance to thermal shock is equally impressive.

White corundum, as it’s also known, is chemically inert. This inertness provides excellent resistance to chemical attacks. It remains stable across a wide range of pH levels.

The properties of white fused alumina include:

- High hardness and toughness

- High melting point and thermal stability

- Chemical inertness and resistance to corrosion

- Minimal porosity and excellent electrical insulation

by Jeroen van de Water (https://unsplash.com/@joenevdw)

White alumina is highly reflective. This quality is advantageous for optical applications. It reflects light efficiently, making it useful in optical lenses.

Its density also deserves mention. White fused alumina’s density ensures precision in various applications. It enables the production of high-strength materials.

These properties collectively make fused alumina incredibly versatile. As a result, industries worldwide incorporate it into various applications. This ensures continued demand and ongoing innovation.

Comparison: White Fused Alumina vs. Other Abrasives

White fused alumina sets itself apart from other abrasives. Its unique properties provide several advantages over alternatives. When comparing abrasives, key differences become evident.

Common abrasives include silicon carbide and garnet. Each has specific attributes, but white alumina outshines them. Its hardness surpasses most standard abrasives.

One significant difference is chemical resistance. White corundum remains inert under severe conditions. This gives it an edge over other materials that might degrade.

Consider its thermal stability. White fused alumina can endure high temperatures. This makes it preferable for applications involving extreme heat.

Below are notable differences:

- Chemical Resistance: Superior to many alternatives

- Hardness: Higher than most common abrasives

- Thermal Stability: Ideal for high-temperature uses

- Purity: Minimal contamination risks

by CARTIST (https://unsplash.com/@lilzidesigns)

Moreover, white alumina provides precise finishes in polishing applications. Its minimal contamination risk is critical in sensitive industries. This purity level is hard to match with other abrasives.

Finally, its recyclability adds further appeal. While not all abrasives can be reused, fused alumina is sustainable. This aspect reduces costs and environmental impact, aligning with modern industrial goals.

Benefits of Using White Fused Alumina

White fused alumina offers multiple benefits across various applications. Its versatile nature makes it a popular choice among industries. This material excels in distinct ways.

A primary benefit is its exceptional hardness. This makes white corundum ideal for cutting, grinding, and polishing. It handles tough materials with ease.

Also notable is its thermal stability. The ability to withstand high temperatures is advantageous. This makes it suitable for environments with extreme heat.

White alumina also offers excellent chemical resistance. It remains stable against various chemicals, reducing degradation risks. This enhances the durability of products using fused alumina.

Moreover, its high purity is another significant advantage. Processes in aerospace, electronics, and healthcare require minimal contamination. White fused alumina meets these stringent requirements with precision.

Key benefits include:

- Exceptional Hardness: Efficient in cutting and grinding

- Thermal Stability: Ideal for high-temperature environments

- Chemical Resistance: Retains integrity against chemicals

- High Purity: Essential for contamination-sensitive processes

Finally, another advantage is its recyclability. White alumina can be reused, contributing to sustainability. This not only lowers operational costs but also reduces environmental impact.

In conclusion, white fused alumina’s unique properties make it indispensable. Industries consistently choose it for its benefits, ensuring high performance and reliability. Its role in modern manufacturing continues to grow due to these beneficial qualities.

Major Industrial Applications

White fused alumina’s unique properties cater to various industries. It serves crucial roles in several applications. Let’s explore these in detail.

In the abrasive industry, white corundum is a key player. Its hardness makes it suitable for grinding, cutting, and polishing. Surface preparation benefits greatly from its use.

Refractory materials also utilize white alumina. Its thermal stability ensures performance in high-temperature environments. This makes it essential in furnaces and kilns.

Precision machining employs white fused alumina frequently. Its purity and toughness allow for meticulous work. Polishing operations also achieve superior finishes with its application.

Electronics benefit from this material’s properties, too. High thermal conductivity aids in cooling electronic components. Its insulating qualities are valuable in many circuits.

The medical and dental fields trust white alumina for its sterility and strength. It finds uses in implants and tools. This reliance highlights its importance in sensitive applications.

Key industrial applications include:

- Abrasives: Cutting, grinding, polishing

- Refractory Materials: Furnaces and kilns

- Precision Machining: Detailed work and polishing

- Electronics: Cooling and insulation

- Medical Uses: Implants and tools

by Lance Rae (https://unsplash.com/@lancer234)

Overall, white fused alumina’s versatility is undeniable. Its application range across industries is broad and impactful. By leveraging its properties, industries enhance efficiency and product quality.

Abrasives and Surface Preparation

White fused alumina plays a significant role in abrasives. Its hardness ensures superior performance. Tools crafted from it withstand intense wear.

Surface preparation also benefits from its use. White alumina grinds and polishes with precision. This prepares surfaces for coatings and finishes.

Abrasive products rely on white corundum for efficiency. It is used in grinding wheels, sandpaper, and blasting media. Each application showcases its unique strengths.

Key benefits in abrasives include:

- Hardness: Effective in wear-intensive processes

- Precision: Achieves desired surface texture

- Efficiency: Enhances processing speed and quality

by Etienne Girardet (https://unsplash.com/@etiennegirardet)

In summary, the abrasive industry thrives on white alumina’s properties. The material ensures top-notch performance and longevity. These qualities drive its choice for abrasive products and surface preparation.

Refractory Materials

The refractories industry relies heavily on white fused alumina. Its high melting point makes it ideal for high-temperature applications. This is crucial in furnaces and kilns.

Its chemical stability ensures long-lasting performance. White alumina resists various chemical attacks. This resilience helps in maintaining structural integrity.

Refractory linings use fused alumina extensively. It is crucial in metallurgical processes, providing thermal insulation. The material’s reliability ensures safe and efficient operations.

Typical uses in refractories include:

- Furnace Lining: Withstands extreme temperatures

- Kiln Components: Maintains structural stability

- Chemical Resistance: Reduces maintenance needs

by Oscar Ramirez (https://unsplash.com/@oscareduardohr)

In conclusion, white fused alumina is vital for refractory applications. Its thermal and chemical properties provide stability. The material ensures that high-temperature processes run smoothly and efficiently.

Precision Machining and Polishing

White fused alumina enhances precision machining. Its fine grit sizes provide exact results. This material is often a choice for detailed work.

Polishing applications benefit from its use. White alumina creates smooth, high-quality finishes. It suits both manual and automated processes.

Its purity limits contamination risks. Industries requiring clean outcomes prefer it. This includes aerospace and semiconductor sectors.

Precision uses include:

- Fine Grit Sizes: Allow detailed machining

- High-Quality Finishes: Achieved in polishing

- Low Contamination Risk: Meets strict industry standards

by NIKHIL (https://unsplash.com/@vinikhill)

Overall, white fused alumina enhances machining and polishing precision. Its adaptability to various techniques is a major advantage. This versatility meets diverse industry needs effectively.

Electronics and High-Tech Applications

White fused alumina is beneficial in electronics. Its thermal conductivity aids in heat management. This property is crucial for sensitive electronic components.

The material also offers great electrical insulation. It prevents unwanted conduction in circuits. This makes it ideal for use in semiconductors and insulators.

White alumina’s purity ensures minimal contamination. High-tech manufacturing often demands pristine materials. Its application in LED lights and chips is widespread.

Key electronics applications include:

- Heat Management: Efficient thermal conductivity

- Insulation: Prevents electrical mishaps

- Purity: Meets high-tech requirements

by Kate Trysh (https://unsplash.com/@katetrysh)

In summary, white fused alumina supports electronic innovations. Its characteristics align with the industry’s strict demands. This fosters the production of advanced devices and components.

Medical and Dental Uses

White fused alumina finds uses in the medical field due to its sterility. Its properties make it ideal for implants and surgical tools. These applications demand high purity and strength.

The dental industry values white alumina, too. It is used for making precision instruments. This ensures durability and hygiene in dental treatments.

Moreover, its biocompatibility is crucial. White alumina doesn’t react with the body. This makes it suitable for long-term applications, like prosthetics.

Medical uses involve:

- Implants: Provides strength and sterility

- Instruments: Ensures precision and hygiene

- Biocompatibility: Safe for long-term use

by Ozkan Guner (https://unsplash.com/@dentistozkanguner)

In conclusion, white fused alumina is indispensable in medical and dental fields. Its properties ensure safety and precision. These characteristics enhance its role in health-related applications.

Environmental Impact and Sustainability

White fused alumina offers several sustainability benefits. It’s derived from high-purity alumina, a naturally abundant resource. This abundance reduces the environmental strain of sourcing materials.

The production process involves electric arc furnaces, which can be optimized for energy efficiency. Advances in technology are making this process greener. Recycling capabilities further enhance its environmental impact.

Additionally, white alumina is inert and poses minimal environmental risks upon disposal. It’s a preferred material in eco-friendly production settings. Many industries value its low environmental footprint.

Key sustainable aspects of white fused alumina include:

- Abundant Resource: Reduces material sourcing impact

- Energy Efficiency: Advancements in greener production

- Recyclable: Enhances sustainability efforts

- Low Disposal Impact: Minimal environmental risks

by Geniele Ribeiro (https://unsplash.com/@geniele)

In summary, while considering environmental factors, white fused alumina stands out. Its sustainable attributes make it a responsible choice. This positions it as a forward-looking material for industries worldwide.

Choosing the Right White Fused Alumina Grit

Selecting the appropriate white fused alumina grit size is crucial for optimizing performance. Different applications require distinct grit sizes for best results. Grit size impacts the surface finish and processing time.

Applications often dictate the required grit size. For instance, a coarse grit may suit aggressive material removal, while a fine grit is ideal for polishing. Understanding the specific needs of your project is key.

When selecting grit, consider factors like material hardness and desired finish. Align these with your operational goals for effective outcomes.

Key factors to consider include:

- Grit Size: Coarse for removal, fine for polish

- Material Hardness: Match grit to substrate toughness

- Application Needs: Align with project outcomes

by Markus Winkler (https://unsplash.com/@markuswinkler)

Ultimately, selecting the right grit enhances efficiency and finish quality. Proper choice leads to cost-effective processes. Tailor grit selection to achieve the best possible results.

Future Trends and Innovations

The future of white fused alumina is vibrant with innovations. As industries evolve, white fused alumina continues to adapt and meet new demands. Emerging technologies expand its applications further.

Advancements focus on improving efficiency and sustainability. New techniques aim to reduce production costs and environmental impact. These improvements promise more eco-friendly and cost-effective solutions.

Innovations in materials science push boundaries with white fused alumina. Research explores enhanced durability and versatility. This innovation pipeline will unlock its potential across multiple fields.

Key future trends include:

- Eco-Friendly Processes: Reducing carbon footprint in production

- Advanced Applications: Enhanced properties for specialized uses

- Cost Efficiency: Streamlining production methods

by Tom Crew (https://unsplash.com/@tomcrewceramics)

These trends highlight white fused alumina’s adaptability. As science progresses, its role in cutting-edge applications expands. The focus remains on achieving superior performance and environmental responsibility.

Conclusion

White fused alumina offers numerous benefits, making it a versatile material for many industries. Its unique properties—such as high hardness, thermal resistance, and chemical stability—position it as a superior abrasive and refractory material. These characteristics make it indispensable in both traditional and emerging applications.

From precision machining to electronics, white fused alumina has found its niche in many sectors. Its environmental advantages, including recyclability and minimal contamination risk, contribute to its growing popularity. As industries seek sustainable solutions, the material’s eco-friendly aspects gain importance.

Looking ahead, innovations in production and application processes promise to expand its utility even further. White fused alumina is well-positioned to meet future industrial demands. Its adaptability ensures it remains a significant player in material science, driven by ongoing research and technological advancements.

[…] The aluminum oxide layer is an integral component in enhancing the performance and longevity of aluminum products. Its ability to provide corrosion protection, improve mechanical properties, and contribute to thermal management underscores its significance in various industrial applications. By understanding the benefits and intricacies of the aluminum oxide layer, industries can harness its full potential, ensuring the durability and efficiency of aluminum-based solutions. […]