In 2025, alumina density ranges from 3.965 to 3.987 g/cm³. You will find that this property plays a key role in industrial performance. When you choose materials, higher alumina density means greater strength, increased hardness, and better wear resistance. For example, as density rises, flexural strength and compressive strength both improve. You also see less material loss in abrasive settings. Each grade and processing method creates small differences in density, which can change how the material performs in your application.

Key Takeaways

- Alumina density in 2025 ranges from 3.965 to 3.987 g/cm³, impacting strength and durability in industrial applications.

- Higher alumina density leads to improved mechanical properties, such as greater hardness and wear resistance, making it ideal for demanding environments.

- Factors like purity, sintering process, and pore structure significantly influence alumina density and its performance in various applications.

- Selecting the right alumina grade based on density ensures optimal performance, especially in industries like aerospace, electronics, and metallurgy.

- Accurate measurement of alumina density is crucial for comparing grades and ensuring the best material choice for specific industrial needs.

What Is Alumina?

Definition and Properties

You encounter alumina in many advanced materials. Alumina, also called aluminum oxide (Al₂O₃), is a white, crystalline substance. It stands out because of its high hardness, impressive wear resistance, and ability to handle extreme temperatures. You can see these qualities in its use for high-temperature measurement tools, such as thermocouple protection tubes. Alumina does not dissolve in water, and it resists corrosion from most chemicals. These features make it a reliable choice for tough environments.

Here is a quick look at some key properties:

| Property | Value |

|---|---|

| Chemical Composition | ~95% Al₂O₃, 1.5% SiO₂, <0.5% Fe₂O₃, 3% TiO₂ |

| Density | 3.965 g/cm³ (at 25°C) |

| Melting Point | 2072°C |

| Boiling Point | 2980°C |

| Hardness | 9 Mohs |

| Solubility | Insoluble in water |

You will notice that alumina density is one of the most important physical properties. It helps determine how strong and durable the material will be in real-world use.

Some of the main features you should remember include:

- High hardness

- Wear resistance

- Low erosion levels

- High temperature resistance

- Corrosion resistance

- Bio-inertness

Industrial Applications

You find alumina in many industries because of its outstanding performance. In electronics, you use it for insulating parts that must survive high heat. In metallurgy and steelmaking, you rely on alumina ceramics for anti-wear linings in equipment. These linings last longer because alumina resists both wear and high temperatures.

You also see alumina in aerospace, machinery, and chemical processing. Its high mechanical strength and thermal stability make it ideal for these demanding settings. When you select alumina for a project, you need to consider alumina density. Higher density means fewer pores, which leads to better strength and wear resistance. This is why industries that need durable, long-lasting materials often choose alumina with higher density.

Tip: Always check the alumina density and microstructure before choosing a grade for your application. This ensures you get the best performance and value.

Alumina Density Values

Standard Density Range in 2025

You will see that alumina density in 2025 falls between 3.965 and 3.987 g/cm³. This range reflects the improvements in processing and quality control that manufacturers have achieved. When you select alumina for industrial use, these numbers matter. Higher density means the material has fewer pores and a more compact structure. This leads to better mechanical strength, higher hardness, and improved resistance to wear. If you work in industries like electronics, aerospace, or metallurgy, you rely on these properties for reliable and long-lasting components.

You can measure alumina density using several laboratory and industrial methods. Here is a quick overview:

| Method | Description |

|---|---|

| Hydrostatic Weighing | Uses buoyancy to measure the weight of displaced liquid when the material is submerged. |

| Pycnometry | Measures the volume of liquid displaced by the material to calculate density. |

| Gas Displacement | Uses a gas pycnometer to measure the volume of gas displaced by the material. |

Note: Accurate measurement of alumina density helps you compare grades and ensure you meet the requirements for your application.

Factors Affecting Alumina Density

You will notice that several factors influence the final alumina density. The most important ones include purity, sintering process, and pore structure.

1. Purity and Composition

The purity of alumina plays a big role in its density. If sodium is present as an impurity, it can lower the density and weaken the microstructure. On the other hand, adding magnesium or iron can help create a denser structure. For example, when zirconia is added to alumina, the bulk density can reach values close to the theoretical maximum. This happens because zirconia improves the sintering process, making the material more compact.

2. Sintering Process

Sintering is the process where you heat alumina powders to bond the particles together. The temperature and time you use during sintering affect the final density. A two-step sintering technique works well. In the first stage, you reach a high relative density. In the second stage, you hold the material at a lower temperature to stop grain growth but allow densification. Prolonged heating in this stage helps you get a denser material with smaller grains. Researchers found that higher temperatures in the second stage and shorter times lead to higher relative density and better properties.

- Two-step sintering achieves high density by:

- Reaching over 70% relative density in the first stage.

- Holding at a lower temperature to suppress grain growth.

- Achieving up to 82% relative density for nanometric powders.

3. Pore Structure

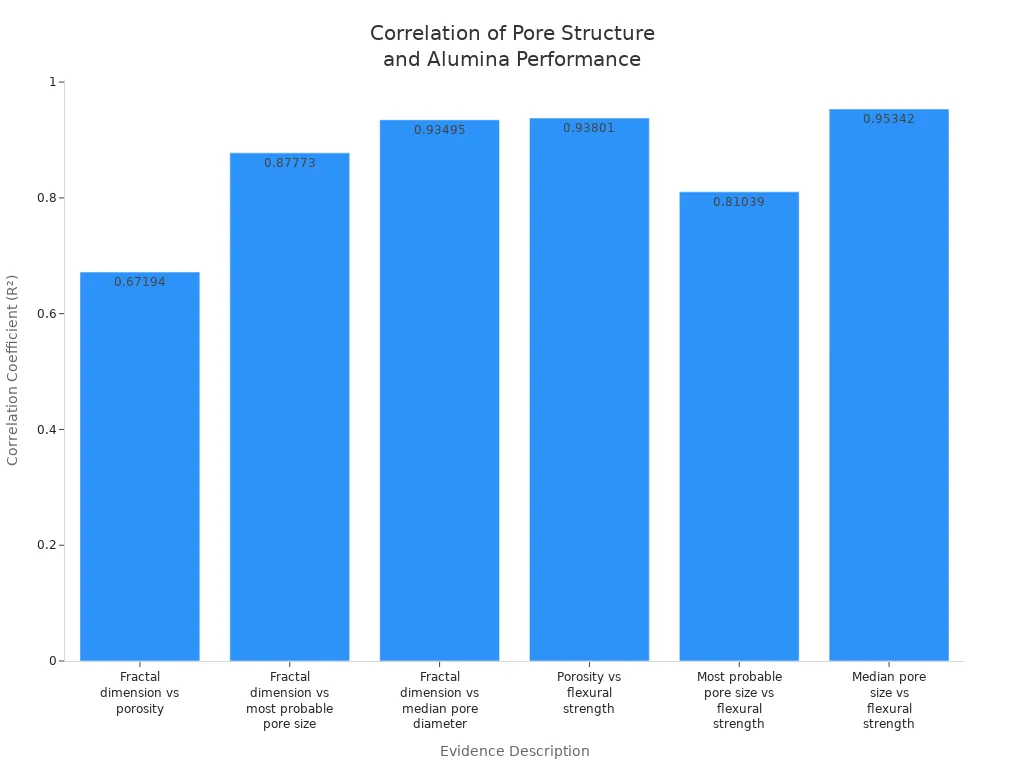

The way pores form inside alumina affects both density and performance. More pores or larger pores mean lower density and weaker material. You can see strong links between pore structure and mechanical strength. The table below shows how different aspects of pore structure relate to flexural strength and density:

| Evidence Description | Correlation Coefficient (R²) |

|---|---|

| Relationship between fractal dimension and porosity | 0.67194 |

| Relationship between fractal dimension and most probable pore size | 0.87773 |

| Relationship between fractal dimension and median pore diameter | 0.93495 |

| Relationship between porosity and flexural strength | 0.93801 |

| Relationship between most probable pore size and flexural strength | 0.81039 |

| Relationship between median pore size and flexural strength | 0.95342 |

4. Advances in Processing Technology

New technologies, such as digital light processing (DLP), allow you to produce alumina ceramics with higher density and better microstructure. DLP helps create intricate shapes and ensures even distribution of particles. This leads to higher flexural strength and more reliable parts. For example, alumina-toughened zirconia made with DLP can reach flexural strengths above 1300 MPa, showing that you can achieve high performance without increasing the amount of solid material.

| Key Findings | Description |

|---|---|

| DLP Technology | Enables intricate production of alumina-toughened zirconia ceramics, enhancing achievable density through improved processing techniques. |

| Flexural Strength | The 35 vol% ATZ exhibited an average flexural strength of 1321 MPa, indicating high performance without the need for increased solid loading. |

| Microstructure | Homogenous microstructures were achieved, suggesting that DLP can produce high-density ceramic parts with tailored properties. |

Tip: When you choose alumina for your project, always consider how purity, sintering, and pore structure will affect the final density and performance.

By understanding these factors, you can make better decisions about which alumina grade to use. You will get the best results when you match the alumina density to the needs of your application.

Grade Comparison

Density by Alumina Grade

You will find that alumina comes in several commercial grades. Each grade has its own density range. These differences happen because of variations in purity and how manufacturers process the material. When you compare grades, you see that high-purity alumina and technical alumina both reach higher density values. Fused white alumina also shows a consistent density. The table below gives you a quick overview:

You should know that higher alumina density means fewer pores and a more compact structure. This leads to better performance in most industrial uses.

Performance Differences

When you look at different alumina grades, you notice clear differences in how they perform. Higher density grades give you better mechanical strength, hardness, and wear resistance. These properties matter when you need materials for cutting tools, linings, or components that face a lot of friction.

Here is a summary of how density affects key properties:

| Property | Description |

|---|---|

| Density | Higher density means a stronger and more uniform material. |

| Hardness | High hardness works well for tools and wear parts. |

| Toughness | Some grades offer better toughness, which helps resist cracking. |

| Flexural Strength | Higher flexural strength helps parts bend without breaking. |

| Wear Resistance | Good wear resistance protects surfaces in contact with other materials. |

You can also compare grades based on their use and cost:

| Alumina Grade | Hardness & Wear Resistance | Impact Resistance | Cost Efficiency |

|---|---|---|---|

| Medium Alumina (75–85%) | Good for light to medium wear | Lower resistance to strong impacts | Most affordable for basic needs |

| High Alumina (92–95%) | Excellent for abrasion and wear | Balanced toughness and hardness | Best value for demanding applications |

| Ultra-High Alumina (99%) | Outstanding wear resistance | More brittle, less impact resistant | Higher cost, used for critical parts |

Tip: Choose the alumina grade that matches your performance needs and budget. High alumina density often means better results, but you should balance performance with cost for your project.

Industrial Impact

Mechanical Strength and Durability

You rely on alumina for its outstanding mechanical strength and durability in many industrial applications. The density of alumina plays a direct role in these properties. When you use alumina with higher density, you get a material with fewer pores and microcracks. This means the material can handle more stress without breaking. In cutting tools and wear-resistant components, you need high yield strength. Alumina with low porosity—over 95% of its theoretical density—delivers this strength. The dense structure prevents cracks from forming and spreading, which helps your tools last longer.

You also see improvements in fracture toughness and hardness when you increase the density. For example, adding nano-sized titanium dioxide to alumina can push the relative density up to 98.25%. This change boosts both toughness and hardness, which are critical for tools that cut hard materials. As a result, you get longer tool life and better performance in challenging environments.

Alumina stands out in advanced ceramics because of its durability and resistance to wear. You can optimize these qualities by controlling the microstructure and grain size. Smaller alumina particles lead to higher density, which gives you better hardness, yield strength, and compressive strength. These improvements make alumina a top choice for demanding industrial settings.

You benefit from alumina’s stability at temperatures above 1600°C. This property is essential for high-temperature processes. The chemical inertness of alumina also protects your equipment from corrosion, even in harsh environments. When you use high-density alumina, you ensure that your components stay strong and reliable, even under extreme conditions.

Here are some key advantages you gain from using high-density alumina:

- Excellent hardness and wear resistance for long-lasting parts

- Stability at very high temperatures

- Resistance to chemical attack and corrosion

- Improved mechanical strength and reduced risk of fracture

Material Selection

You need to select the right alumina grade for your application to get the best results. Engineers and material scientists use alumina density data to match materials to specific needs in fields like aerospace, automotive, biomedical, and electronics. High density means better mechanical and physical properties, such as hardness, stability, and thermal resistance. These qualities are critical when you need reliable performance.

When you choose an alumina grade, you should follow clear guidelines. Start by defining your application needs. Think about the temperature, wear intensity, and chemical exposure your material will face. For harder materials or more demanding environments, use alumina grades with 92% or higher content. Finer grains in the microstructure give you more durability and lower the risk of fracture.

You can use the table below to guide your selection process:

| Guideline | Description |

|---|---|

| Define application needs | Consider high temperature, wear intensity, or chemical exposure when selecting alumina grades. |

| Match alumina content | Use 92% or higher grades for harder materials to ensure effective milling. |

| Consider microstructure | Finer alumina grains enhance durability and minimize the risk of fracture. |

| Size selection | A combination of ball diameters can enhance milling uniformity and energy transfer. |

| Match forming process to milling mode | Rolled balls are better for wet milling, while isostatic-pressed balls are suited for dry milling. |

| Factor in supplier reliability | Ensure a consistent production process and technical support for long-term performance. |

| Evaluate cost-effectiveness | High-grade materials may have a higher upfront cost but offer long service life and low wear rates. |

You should also consider the cost-effectiveness of your choice. High-density alumina, such as calcined or tabular types, offers high melting temperatures and strength retention. These features make them valuable for ceramics and refractory production. The price of high-density alumina reflects its quality, but you often save money in the long run because the material lasts longer and reduces downtime.

In mass production, maintaining consistent alumina density is important for product quality. High-density alumina grinding balls, for example, show very low wear rates and keep your process stable. They do not contaminate your product, unlike steel media, which can release iron particles. Consistent density ensures that your products have the same particle size and chemistry in every batch.

You may face challenges in keeping alumina density consistent during large-scale manufacturing. You need to control purity, synthesis, and processing. Monitoring tensile strength, diameter uniformity, and porosity helps you achieve reliable results.

Tip: Always match the alumina density to your application’s demands. This approach gives you the best balance of performance, durability, and cost.

You need to understand alumina density to make smart choices for your industry. The table below shows why density matters for performance and reliability:

| Property | Importance in Industry |

|---|---|

| High Melting Point | Ensures thermal stability and structural integrity in high-temperature environments. |

| Low Thermal Expansion Coefficient | Reduces cracking risk under rapid temperature changes. |

| Chemical Stability | Resists reactions with molten metals and corrosive gases. |

Grade and density differences shape how you select materials. High-purity alumina works best for electronics and aerospace, while lower grades fit industrial needs.

By 2026, you will see more eco-friendly and digital technologies shaping alumina production and density optimization.

Always use density data to match alumina to your application for the best results.

FAQ

What is the typical density range for alumina in 2025?

You will find that alumina density in 2025 usually falls between 3.965 and 3.987 g/cm³. This range reflects improvements in purity and processing. You can use these values to compare different grades for your application.

How do you measure alumina density?

You can measure alumina density using methods like hydrostatic weighing, pycnometry, or gas displacement. Each method gives you accurate results for different sample types. Always choose the method that matches your material form.

Why does alumina density matter for industry?

You rely on alumina density to predict strength, hardness, and wear resistance. Higher density means fewer pores and better performance. You should always check density when you select materials for demanding environments.

How do you choose the right alumina grade?

Tip: Start by listing your application needs. Match the alumina grade to your requirements for hardness, toughness, and cost. High-density grades work best for high-wear or high-temperature uses.

What factors can change alumina density?

| Factor | Effect on Density |

|---|---|

| Purity | Higher purity increases it |

| Sintering | Better sintering raises it |

| Pore Structure | Fewer pores boost density |

You should monitor these factors during production for consistent results.